Custom Pulleys: 2026 3d Printing Revolution Cuts Lead Times By 60% Politics Intellectual Property Challenges For The

This table compares key challenges in managing metal 3d printing lead times, highlighting how each affects duration and b2b strategies They reliably transfer the power to the axes and make every detail of your print possible 3d printing empowers companies to produce spare parts exactly when and where they're needed—slashing inventory costs, minimizing lead times, and ensuring critical parts are always available

3D Printing Dental Market Entrant Into the USA – 3D Printing Revolution

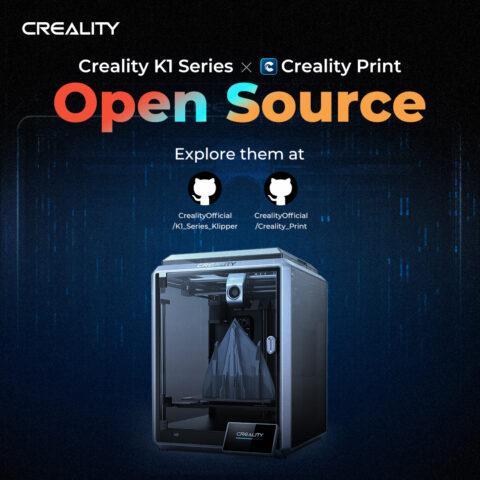

Paradigm manufacturing's advanced additive manufacturing solutions make this transformation accessible, sustainable, and reliable. 3d printer belts belts for 3d printers belts are essential components of a 3d printer that ensure precise movements and exact print results The below is a summary of my recent article on 3d printing

3d printing, also known as additive manufacturing, is poised to redefine how industries operate, from manufacturing to medicine and construction

In the era of industry 4.0, 3d printing, or additive manufacturing (am), has revolutionized product design and manufacturing across various sectors This review explores the evolution of 3d printing technology and its impact on industrial innovation, highlighting advancements in aeronautics, the automotive industry, and biomedicine Various am processes, such as binder jetting, direct energy. For example, 3d printing can help companies meet demand in real time in situations when long lead times are a problem

It also can help lower inventory costs by enabling companies to maintain a virtual inventory and print parts as they need them. Additive manufacturing (am), often referred to as rapid prototyping, freeform fabrication, or 3d printing, is defined as the process of joining materials to make objects from 3d model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies like machining [1,2] Various industries refer to the practice of swiftly producing a physical model of a part or system. From prototyping to production, 3d revolutionaries—innovative companies and technologies—are redefining how goods are designed, produced, and delivered.

More than 40% of 1300 users of 3d printing view reduced lead times as one of the benefits of the technology, according to the 2019 state of 3d printing survey by sculpteo

This is seen as an even bigger benefit for users in the industrial goods sector, with nearly 60% of respondents in this category citing lead times as a benefit. Metal 3d printing vs manual fabrication in 2026 At met3dp, a leading provider of metal 3d printing services, we've witnessed firsthand how this shift reduces lead times from months to weeks, cutting costs by up to 40% for small batches. This comparison table illustrates key differences between traditional machining and metal 3d printing for valve components

How 3d printer technology transforms iphone accessory manufacturing with custom solutions, reducing costs and enabling rapid production. Explore the evolution of 3d printing from prototypes to medical marvels, construction feats, and aerospace advancements See how this technology is reshaping industries worldwide today! Discover how 3d printing evolved from consumer hype to industrial powerhouse

If the global engineering and manufacturing community plans to keep unlocking the full potential of industrial 3d printing, together they will have to keep rethinking the fundamentals of design engineering and digital factories of the future

The global 3d printing community has grown exponentially. What are the 2022 3d printing trends that additive manufacturing experts consider the most important To fully harness the transformative potential of 3d printing in healthcare, collaborative endeavors amongst academicians, clinicians, industrial entities, and regulatory bodies are paramount