Understanding The Percentage Of Thread Engagement For 3/4 10 Tap Drill Size Engine Pro

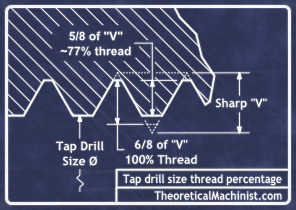

The size of the tap drill hole for any desired percentage of full thread depth can be calculated by the formulas below. This figure (.0485), when subtracted from the.250 diameter, is.2015, which is the required diameter of hole. Percentage of thread and tap drill selection

Npt Thread Chart Tap Drill Size - Infoupdate.org

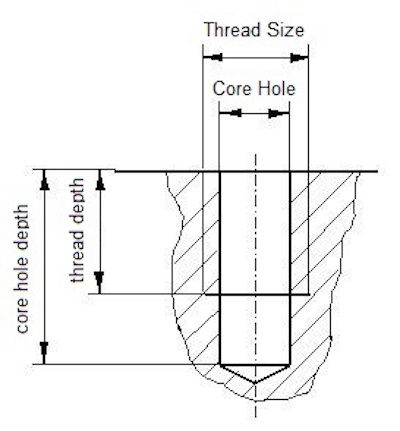

Many variables affect the performance of threaded holes and the taps used to generate them Includes fractional, metric, and numbered screw sizes, decimal equivalents, pitch, and recommended tap drill sizes for threading operations. One very important factor is the drill size used to produce the hole that will be tapped

Most tap drill charts call out only one tap drill size, and that will produce an approximate 75 percent thread

In general, tap tool life can be increased significantly. Tap drill size size formula's are theoretical based on the thread type and desired percentage of thread Please allow for the fact that drills generally drill oversize. Tap drill size calculator for inch and metric threads (for cutting and forming taps)

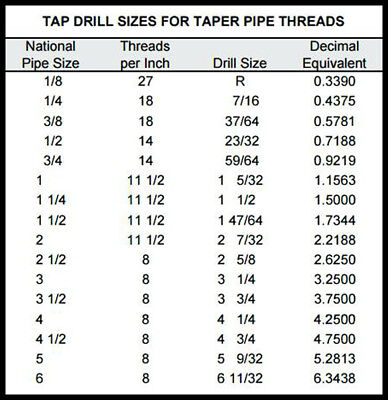

Plus formulas and charts for tap drill size. For internal thread, tolerance classes 1b & 2b and 3b are available For general use, select 1b & 2b thread class For length of engagement, options are l ≤ 0.33d, 0.33d ≤ l ≤ 0.67d, 0.67d ≤ l ≤ 1.5d, 1.5d ≤ l ≤ 3.0d.

Here's what makes this calculator different

You can adjust the thread percentage to match your application Standard tap drill charts only show 75% thread engagement, but that's not always optimal Lower percentages make tapping easier and extend tap life Higher percentages give maximum thread strength when you need it

A common internal thread, drilled so that it results in 50% of full thread will break the external thread, before the internal thread will strip A common internal thread drilled out so that it contains 100% of full thread is only 5% stronger than a 75% height of thread, yet it requires 3 times the power to tap. The drill and tap size calculation determines the appropriate drill bit size needed before tapping threads The formula accounts for the major diameter of the thread, the percentage of thread engagement desired, and the threads per inch (tpi).

75% engagement provides optimal strength (87% of full thread) with reasonable tap life

Adjust drill size up for harder materials or use 65% engagement (smaller drill) for maximum strength in soft materials. A thread engagement chart is a useful tool for determining the appropriate thread engagement for a given fastener and application These charts typically provide a range of recommended thread engagement percentages for different fastener types and materials, as well as the corresponding lengths of thread engagement in inches or millimeters. Basic thread dimensions (pitch, minor & major diameters, depth, lead), tolerance range for all applicable classes and much more

Understand thread engagement for selecting fasteners Learn to calculate and choose appropriate engagement for strength. Unit conversion calculator to convert the following units acceleration, area, torque, electrical, energy, force, force / length, length, light, mass, mass flow. Use our tap drill charts to find the right drill size for screws or bolts and ensure perfect threading every time.

Before diving into the specific drill bit size for a 3/4″ tap, it's crucial to grasp the fundamental relationship between thread sizes and drill bit selection.

Learn about the crucial 21/32 inches bit selection, securing the setup, lubrication, and gradual tapping progress for flawless results Dive into the significance of precision to avoid thread issues and explore the advantages of depth stops for impeccable drilling precision in every operation. Confounded by what size drill bit you need for a 3/4 tap This article navigates the complexities, clarifying tap and drill compatibility, thread matching, and lubrication tips

Learn the steps to determine the correct drill size, from identifying tap dimensions to fitting tests, ensuring smooth diy projects. The tap drill size of a hole that will be cold form tapped is usually bigger than it cutting tap counterpart (77% thread is what you want to use) a 100% thread is 3/4 qtr, or (6/8 th), of the full 60° triangle which is the maximum allowed height of a full thread, the v shape, including flats. A tap size chart can help you determine the correct drill bit size for your 3/4 tap

The chart typically lists the tap size, the corresponding drill bit size, and the thread count.

Tap drill size calculator for ansi unified inch screw threads Calculations are done for thread sizes from 0.060 to 2 inch. Speeds & feeds din standards thread mill cnc program generator tap drill calculator milling performance optimizer contact tech support Comprehensive tap size chart for manufacturing and machining