Understanding The Interaction Between Belts And Modern Synchronous Sprockets

Synchronous belts are defined as belt drives that have teeth and corresponding grooves on pulleys, allowing for positive angular location without slipping, thus maintaining a constant speed ratio between driving and driven shafts The solar system has one star, eight planets, five dwarf planets, at least 290 moons, more than 1.3 million asteroids, and about 3,900 comets. They are commonly used in applications requiring precise motion sequences or indexing.

Gates Synchronous Sprockets for Industrial Timing Belts | Poly Chain

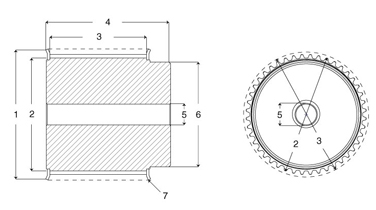

Understanding synchronous belt drives many components of a synchronous power transmission belt interact with each other and combine to produce its performance characteristics To understand how sprockets work, it's important to consider their interaction with other drivetrain components, particularly the chain and pedals. Obvious features, such as reinforcement cord and a variety of elastomeric materials, are very important to the belt carcass.

Understanding the positive engagement mechanism in synchronous belts synchronous belts work by transferring power via those little teeth that fit right into the grooves of their corresponding sprockets

Instead, they create actual physical contact points between the belt and sprocket, which keeps everything aligned. And the comparison to roller chain drive systems is even more stark. The terms timing belt and synchronous belt are often used interchangeably to describe a class of toothed, positive drive belts But while the function of a timing belt is primarily synchronization, industrial synchronous belts have evolved into a power transmission system that rivals roller chain.

For centrifugal fans and pumps, which exhibit a strong relationship between operating speed and power, synchronous belt sprockets must be selected that take into account the absence of belt slippage. Types of belt drives con't synchronous belts, or timing belts, ride on sprockets that have mating grooves that the teeth on the belt seat This is a positive drive, limited only by the tensile strength of the belt and the shear strength of the teeth From large rock crushers to tiny sewing machines, the variety of applications is wide.

Small pitch synchronous drives operating at speeds of 50 ft/min (0.25 m/s.

Students are responsible for knowing and understanding regulations and policies, and for meeting all deadlines and requirements of admission, registration and degree programs Failure to read the information provided will not be considered an excuse for noncompliance. We would like to show you a description here but the site won't allow us. Belt drives are described along with different types, working procedures, selection, advantages, disadvantages, power transmission, etc.

Globalization is the process of increasing interdependence and integration among the economies, markets, societies, and cultures of different countries worldwide This is made possible by the reduction of barriers to international trade, the liberalization of capital movements, the development of transportation, and the advancement of information and communication technologies In this article, we will discuss the differences between cogged drive belts and pulleys and their advantages and disadvantages What are cogged drive belts and pulleys

Cogged drive belts are also known as toothed or synchronous belts, due to their design of having teeth or cogs on the inner surface of the belt.

In this ultimate guide to sprockets, learn about what sprockets are, the types of sprockets, what they are used for, and how to tell if a sprocket is worn. Toothed rubber belts [3] a toothed rubber timing belt, also known as a synchronous belt, is a crucial component in an internal combustion engine It is made of durable rubber and features teeth on its inner surface that mesh with corresponding grooves on the crankshaft and camshaft pulleys. Attention bookstores, wholesalers, schools, and corporations

Asq quality press books, video, audio, and software are available at quantity discounts with bulk purchases for business, educational, or instructional use How do sprockets work on bikes basic working principle the sprocket, an essential component in a bicycle's drivetrain, plays a pivotal role in defining a bike's performance