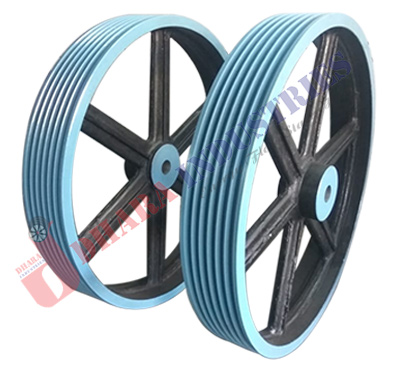

The Relationship Between Groove Angle And Grip In Modern V-belt Pulleys V Belt

When a belt is tensioned and fitted into the groove, the angled sides of the belt press firmly against the angled sides of the pulley groove Same and next day delivery. This design allows for superior frictional grip compared to flat belt systems, making it less prone to slipping even under high load.

Pulleys & Belts

Our application technology experts offer you free support service regarding the application of our products and also help solve your drive problems. The v shape of the belt tracks in a mating groove in the pulley (or sheave), with the result that the belt cannot slip off The groove angle determines the type of belt that can be used and affects the belt's grip and tracking

The dimensions of the groove impact the type and size of the belt that can be accommodated.

An optimal groove angle ensures that the ribs are in firm contact with the pulleys, which significantly reduces the chances of slippage. V and flat belt design guide, equations, and information v and flat belt design and engineering data belt tensions, pretensions, torques, power and configurations A small groove angle will require more force to pull the belt out of the groove which will result in loss of power and excessive belt wear due to friction and heat Hence the selected groove angle is a compromise between the two

Usually, the groove angles of 32° to 38° are used. A little consideration will show that the wedging action and the transmitted torque will be more if the groove angle of the pulley is. Belt tension imagine that both pulley wheels are completely free to turn and that the belt is initially tensioned by stretching the centre distance between the wheels (in practice a spring loaded wheel pushing against the belt is used to tension the belts)

The tension in the belt will be the same along its whole length and equal to f

When transmitting power, the driven wheel will be. I'm assuming the angle is standard, and that width and depth are the only variables for the different cross sections for belts Is this the sort of thing tha would be in a machinery's handbook? Friction coefficient the friction coefficient (μ) of any belt is directly dependent upon the length of contact it has with its pulley

A simple rule of thumb may be used to assess the grip on any pulley, based upon a design grip (μ) being achieved for a contact angle (α) of 180° (fig 2) And belt drives for power transmission The latter offer several advantages and come in two main subtypes — v belt and synchronous belt dri es — motors Optibelt de méxico s derl decv r.f.c

Llc „optibelt power transmission optibelt power transmission india pvt

Optibelt power transmission (shanghai) co., ltd Optibelt gmbh (filiaal belgie) optibelt colombia s.a.s Learn more about its features here. V belt pulleys offer high speed power transmission that is resistant to misalignment and slipping.

Critical parameters for pulley selection belt type and profile Affects speed ratio (ratio = driver pulley diameter / driven pulley diameter) Consider a vee section belt with an included angle of 2.vee belts grip on the side and not on the bottom The wedging affect increases the reaction force between the pulley and the belt from r to r'.

1 showing effect the f bending o april 22, 1954

The maximum permissible tension in the belt is limited to 2.2 kn The angle of lap is 170° and the groove angle 45° If the coefficient of friction between the belt and pulleys is 0.17 Velocity of the belt for maximum power, and 2