The Physics Of Torsional Stress Management On A High-speed Pulley Shaft Torque Drive Shft Downlod Scientific Digrm

Stress in axial planes shaft deformations Cram.com makes it easy to get the grade you want! The angle of twist of the shaft is proportional to the applied torque ϕ ∝ t ϕ ∝ t the angle of twist of the shaft is proportional to the length ϕ ∝ l ϕ ∝ l the angle of twist of the shaft decreases when the diameter of the shaft increases sign.

China Professional SPA CZPT Spz Sheave Tension Tapered Shaft V Belt

Mechanics of materials axial shear components • torque applied to shaft produces shearing stresses on planes perpendicular to shaft axis Quickly memorize the terms, phrases and much more • existence of axial shear stresses is demonstrated by considering a shaft made up of axial slats

Slats slide with respect to each other when equal and opposite torques applied to shaft ends.

What is the importance of torsional stress Torsional stresses may cause elastic or plastic deformation to a shaft, and so shafts must be designed to properly resist torsional stresses How does torsional stress work Torsional stress works in much the same way a.

Shaft stress refers to the internal forces acting on a shaft during operation Understanding the mechanics of stresses in a shaft is essential for engineers to design reliable and durable shaft systems In this article, we will discuss the different types of stresses that can occur in a shaft, how to calculate them, the causes of stress concentrations in shafts, and the various methods used to. Shear stress in the shaft when a shaft is subjected to a torque or twisting a shearing stress is produced in the shaft

The shear stress varies from zero in the axis to a maximum at the outside surface of the shaft.

In operation they are subjected to Torsional deformation torque is a moment that twists a structure Unlike axial loads which produce a uniform, or average, stress over the cross section of the object, a torque creates a distribution of stress over the cross section To keep things simple, we're going to focus on structures with a circular cross section, often called rods or shafts.

A common design problem is the determination of the required size of a shaft so that it will transmit a specified amount of power at a specified speed of revolution without exceeding the allowable stress consider a motor drive shaft, rotating at angular speed Knowing t and the allowable shear stress for the material;t allow we can determine the size of the shaft's cross section using the torsion formula, assuming linear elastic behavior Torsion in shafts is found in many industrial applications, especially in drive shafts of vehicles This chapter first explains the variation of shear stress in a shaft under the action of a torque

Mathematical expressions have been derived for the shear stress,.

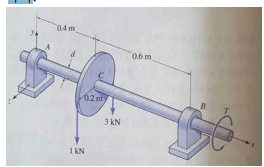

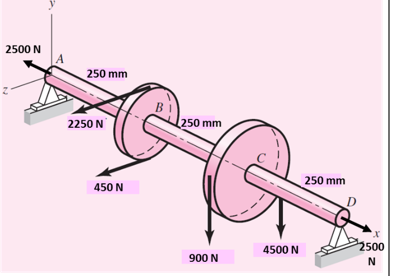

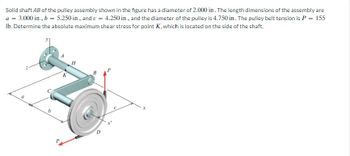

E) determine the tensions in the belt on pulley b, assuming the shaft is running at a constant speed B) find the magnitudes of the bearing reaction forces, assuming the bearings act as simple supports. The shaft for pulley and the idler must be designed to handle stress and deflection criteria The deflection criteria are needed to provide ample life for the product carried by the shaft, not necessarily the shaft itself.

The speed pulley calculator calculate the output speed of a pulley based on the input speed of a driving pulley and diameters of both pulleys. Calculate the belt drive system parameters like speed, belt length, rpm, torque, belt tension using pulley calculator Check the step by step process, formulas. A hollow steel shaft is to transmit 4200 n · m of torque and is to be sized so that the torsional stress does not exceed 120 mpa

( a ) if the inside diameter is 70 percent of the outside diameter, what size shaft should be used?

Shaft design procedure because of the simultaneous occurrence of torsional shear and normal stresses due to bending, the stress analysis of a shaft virtually always involves the use of a combined stress approach The recommended approach for shaft design and analysis is the distortion energy theory of failure. Pulleys, blocks and tackles.block, tackle or pulley calculator the calculator below can be used to calculate effort force in block, tackle or pulley construction The calculator can be used for metric and imperial units as long as the use of units are consistent

A transmission shaft carries a pulley midway between the two bearings The bending moment at the pulley varies from 200 nm to 600 nm, as the torsional moment in the shaft varies from 70 nm to 200 nm The frequencies of variation of bending and torsional moments are equal to the shaft speed. Lastly, the applied torque has a significant influence on the angle of twist experienced by a shaft

Greater torque leads to a larger angle of twist, resulting in more shear stress and potential deformation

When the applied torque exceeds the material's yield strength or the shaft's torsional stiffness, it may cause the shaft to fail. Critical speed is the speed at which the shaft vibrates at its natural frequency, leading to resonance and potentially catastrophic failure. We would like to show you a description here but the site won't allow us. Stresses/deflections shafts in torsion 8.1 an introductory exercise problem of torsion of circular shafts

Study flashcards on shaft at cram.com