The Design Philosophy Of Dualvee Tech At Bishop Wisecarver Corporation Pdf Calogs Nical Documention

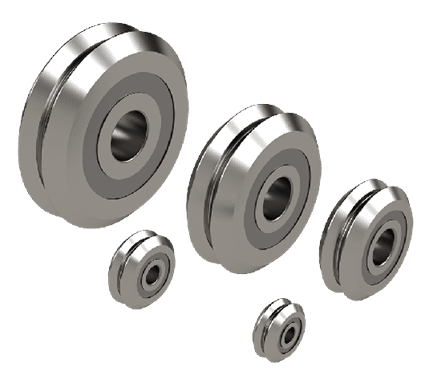

De and figure 2 dualvee motion technology® (left) vs Our eccentric bearing feature allows for easy replacement of the guide wheels and wheel plate when assembled within your. Alternative recirculating bearing technologies (right)

DualVee - BISHOP-WISECARVER - PDF Catalogs | Technical Documentation

Rolling contact between wheel and track sweeps debris aside making dualvee® ideal for use in contaminated environments. We make component selection simple. Through the integration of our mechanical, electronic, software, control and systems design engineering expertise (mechatronics), 60+ years of experience, and.

Based on double row angular contact bearing technology, the original dualvee® design has provided reliable and versatile guidance in many industries and operating environments

The single edge track design is. In 1968, bud wisecarver invented dualvee motion technology (dmt) to provide a solution for harsh environment applications where existing technologies were ineffective Dualvee also proved excellent for long length, smooth motion and low noise requirements. In 1967, bud wisecarver invented and patented dualvee motion technology® to provide a solution for harsh environment applications where existing technologies were ineffective.

From factory automation projects to oem designs, dualvee motion technology components and assemblies provide the design flexibility for virtually any guided motion application Based on the dualvee guide wheel, this technology offers a level of reliability that is unmatched in the industry Our linear and rotary motion solutions, custom complex assemblies, and embedded intelligence systems lead the manufacturing industry, and they are backed. Utilitrak® the utilitrak linear guide is designed primarily for transport applications where low cost, easy installation and minimal maintenance are primary design objectives

Constructed with proven dualvee motion technology®, utilitrak offers high reliability and smooth motion in a sleek, compact design.

This helps customers to ensure the accuracy and repeatability of their operations. Provide time proven, economical solutions for all types of application environments Our motion components are engineered to integrate seamlessly into machine designs, supporting a wide range of automation and structural applications. These distinctive vee guide wheels and track provide quiet, low friction motion in even the most extreme conditions.

Get the latest technical specifications, availability, and pricing