The Chemical Engineering Behind The World-famous Gates Rubber Compounds Precision Associates

Synthetic elastomers are produced on an industrial scale in either solution or emulsion polymerization methods Learn how these chemical combinations shape our world! (solution polymerization and emulsion polymerization are described in the article chemistry of industrial polymers.) polymers made in solution generally have more linear molecules (that is, less branching of side chains from the main polymer.

Natural rubber industry unites behind GPSNR's Assurance System - Rubber

Chemistry and applications describes the production, processing, and characteristics of a wide range of materials utilized in the modern tire and rubber industry, from natural to butyl rubber, carbon black, silica, silanes, and beyond. Discover 10 examples of compounds and their vital roles in daily life, from water to glucose A lot of developments have occurred in rubber compounding to improve the final performance

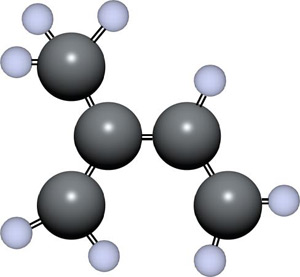

Natural rubber natural rubber, also called india rubber or caoutchouc consists of polymers of the organic compound isoprene

Composition, types, properties, and applications in automotive, healthcare, and industrial use with modern rubber compounding techniques. In this blog, we explore the rubber manufacturing process in detail, including the stages involved. This is a review of the basic materials used in designing many common types of rubber products The development of the combination of materials contained in a usable rubber compound involves many disciplines that include chemistry, physics, mathematics, and polymer science.

The feedback loop allows for both processing and engineering units to improve their products optimally This holistic approach ensures consistency and quality throughout the manufacturing process, transforming the rubber compound into the final product with precision and efficiency. The next stage in production involves the irreversible chemical process known as vulcanization, which fundamentally alters the compound's molecular structure This transformation is achieved by applying controlled heat and pressure to the prepared rubber mixture

Historically, heating rubber with sulfur yielded a vastly superior.

The role of rubber compound manufacturers in india india is home to some of the best rubber compound manufacturers in the world Read our breakdown of how chemistry and careful ingredient selection are utilized to develop your desired properties in a rubber product. Resistance table notes & legal water & air // multipurpose essential water master d. Or that polythene, the world's most common plastic, was accidentally invented twice

The chances are you didn't, as chemistry tends to get overlooked compared to the other sciences. Learn about rubber compounds, their formation through blending materials, the mixing process, key equipment, and applications in industries like automotive, aerospace, and construction. Guide to racing tires tech Components, compounds, tread, sizing for grip, durability, lap times

Essential for optimal tire selection.

Behind the scenes, chemical engineers apply principles of chemistry and physics to solve complex problems, ensuring that every cup of coffee meets the high standards expected by consumers worldwide In this article, we will explore the fascinating journey of coffee as it travels from the fields to your cup. A number of chemical materials are used in the manufacture of the brazuca, the world cup football The majority of these materials are polymers

These are very long molecules built up from many smaller component molecules. Silicone rubber compounds are versatile materials used across industries for their durability, flexibility, and resistance to extreme environments Explore the principles of rubber formulation in our complete guide Learn about types, processes, and applications to enhance your expertise!

Explore 10 different types of rubber, highlighting their advantages, disadvantages, and typical uses

Find different types of rubber parts here at martins rubber. This chemical reaction transforms rubber from a soft, sticky material into a durable, elastic compound capable of withstanding extreme conditions. It is not unusual to encounter end use conditions that are often harsh, putting heavy demands on electrical performance, temperature, chemical resistance, etc.