The Centrifugal Force Limits Of Standard Retaining Rings For Shafts Din 6799 Ring E

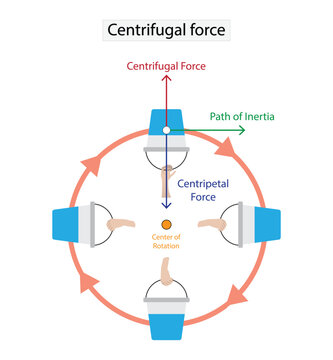

A smalley retaining ring, operating on a rotating shaft, can be limited by centrifugal forces The origin of the self locking spiral retaining ring all circlips for rotating shafts are subject to centrifugal force. Failure may occur when these centrifugal forces are great enough to lift the ring from the groove.

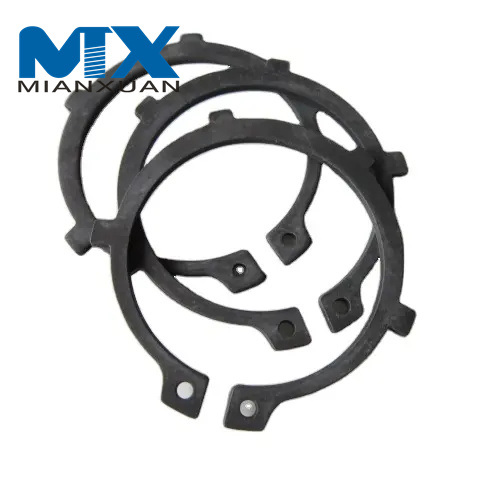

Buy Wholesale China Metric Din 471 External Retaining Rings For Shafts

Centrifugal forces limit all retaining rings operating on a rotating shaft The purpose of this specification is to define a minimum common set of supplementary requirements for procurement of centrifugal pumps in accordance with ansi/api standard 610 11th edition september 2010 centrifugal pumps, which is an identical adoption of iso 13709:2009 with the same title, for application in the petroleum and natural gas. If the centrifugal forces (see figure below) are significant enough to expand and lift the retaining ring from the groove, that's when ring failure usually occurs.

Applications of large retaining rings that tend to spin in their grooves when subjected to sudden acceleration or deceleration of the retained part can benefit from a ring with more cling (i.e., a smaller interior diameter) as long as the stress of installation is within permissible limits.

A retaining ring operating on a rotating shaft can be limited by centrifugal forces When these forces are great enough to lift the ring from the groove, it may fail The following equation calculates the speed at which the force holding the ring on the groove (cling) becomes zero The retaining ring may fail when the assembly is accelerated.

Retaining ring, constant section ring, or tapered section retaining ring (circlip) For low to moderate rotational capacity requirements, a standard spirolox retaining ring may work. Huyett but when an external retaining ring is used on a rotating shaft, centrifugal forces can cause the ring to lift out of its groove, leading to ring failure, so maximum speed becomes an important selection factor as well. When selecting the retaining ring, check both the shaft diameter and the groove diameter before use

When using the retaining ring on a rotating shaft, the ring may drop off since it will spread due to centrifugal force.

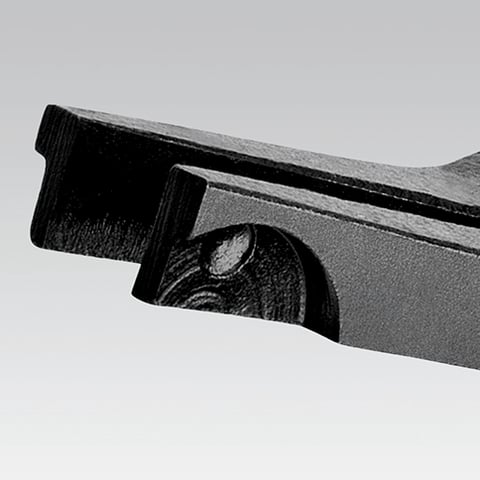

How the ring is to be installed will affect the type of ring you select If installation is axial, (along the axis or center point of a shaft/housing), you will need an axial retaining ring These include ho, sh, hoi, shi, shr, shm rings listed in the axial ring section of the catalog Axial, along the center point of a shaft or housing.

A retaining ring, also known as a snap ring or circlip, is a special fastener Retaining ring design calculation it keeps parts together in housings, shafts, and bores. This guide will help you understand the different types of retaining rings and the function of each The differences are subtle, but important

Understanding what type of retaining ring to use in a particular application could result in enormous savings in time and costs on your next fastener project

We welcome your questions as well as your comments on this guide Spacer ring (4) when using the retaining ring on a rotating shaft, the ring may drop off since it will spread due to centrifugal force Be sure to verify the conditions by using the actual machine. Same and next day delivery.

Depending on the requirements, the retaining rings are also available in different sizes, thicknesses and shapes. The thrust load capacities shown in the table below include safety factors. From installation to specifications to types and tools, our retaining ring guide covers everything Learn how to choose the ideal retaining ring for any application!

The axially assembled din 471 are retaining rings for shafts, widely used

They can transmit high axial load between the element of the machine that exerts the force and the groove in which the ring is assembled. Laminar ring is a metallic spiral retaining ring made from coiled flat wire Is a dedicated laminar seal ring manufacturer based in china Laminar rings have the characteristics of a labyrinth seal, the labyrinth gap effect will lead some penetrated liquid back by centrifugal force

It is mainly used for the bearings. Centrifugal force is a physical force that tends to throw the rotating propeller blades away from the hub Torque bending force, in the form of air resistance, tends to bend the propeller blades in the direction opposite that of rotation. Centrifugal forces on external retaining rings mounted on rotating shafts limit rpm

The rpm at which the force holding the ring on the groove goes to zero, n, is found by: