Techies Debate Synchronous Sprockets Noise Reduction In Office Robots Mart

This paper examines various techniques for vibration control and noise reduction, with a particular focus on their applications in robotics, automotive, aerospace, and industrial machinery. How does the sprocket ratio affect performance? A study from 2019 found that when asked to perform a synchronous task with a robot, participants were relying on the actuator or gearbox noise more than visual cues from the robot.

Engineered synchronous sprockets improve drives using curvilinear belts

In practical applications, robots inevitably encounter noise interference, which can lead to suboptimal performance in coordinated motion control A higher sprocket ratio (larger \ (t2\) compared to \ (t1\)) means a reduction in output velocity, which can increase torque and decrease speed We have measured the noise generated by three transmissions by synchronous belts of type at10, bat10 and sfat10

Discover the latest articles, books and news in related subjects, suggested using machine learning

Transmission system noise can come from many components. Despite continuous advances in actuator technology, there are very few systems that can claim to be silent. Although synchronous, or toothed, belts are quieter than chains, synchronous belt noise levels can be unacceptable for some applications and environments. Currently, robots on the market have varying operational requirements due to their different functions

The care robots are primarily used to serve people under care Therefore, reducing the amount of noise they make while moving is important This study measured their noise in an anechoic room. It's important to reduce vibration and noise in industrial robots

This ensures the robots are reliable, safe, and easy to use

Developers need to design flexible parts, choose the right materials, and use techniques to stop vibrations This helps solve the problems robots face in their work. This may turn into a 'teachers v techies' debate, says elletson, but it's an opportunity to kick important ideas around It'll be fun, there'll be lots of noise and, at the end of the evening, we'll all know a lot more about the potential for artificial intelligence in education and the issues involved in developing it.

Bringing people together is what telepresence robots do best Accessible from anywhere, they help office workers collaborate seamlessly or bring friends and family together How does a telepresence robot work Unlike a regular video call, with a telepresence robot, you can be present in the room with your clients as if you were there.

When using sprockets and chain in a multi stage reduction, it's very common to use gears for the first stage and then use sprockets and chain for the last stage.

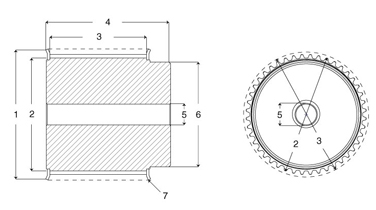

Calculate sprocket speeds using teeth ratio Driven rpm = (driver rpm × driver teeth) / driven teeth Essential for bikes, machinery & conveyors. There are three components associated with synchronous belt noise

Impact between the teeth and sprocket causes a slapping sound. For example, the sound level is also determined by the tolerances of the chain and sprockets Dc6v gear motor 30rpm 0.5w high torsion low noise gear box speed reduction for robots info: Martin sprocket and gear inc

Tired of noisy idler sprockets

Learn the common causes of sprocket noise and discover effective solutions to reduce or eliminate it Mds of michigan offers expert advice and maintenance tips. Pbr has developed an innovative range of 18nc sprockets called rss (rubber sprocket system) Continuous improvement and innovation continuous improvement and innovation are crucial for noise reduction in industrial sprockets

Manufacturers should invest in research and development to explore new techniques, materials, and designs that can further minimize noise levels. Get your hts pulleys today! The operating voltage is dc24v, which can be forward and reverse rotation, smoother movement, large torsion, low noise, and long life Permanent magnet motor, strengthened magnetic tile, no.

Gates sprockets are specially designed for synchronous belts to provide optimal performance and exceptional results

Check our high quality poly chain gt sprockets, powergrip gt2 and gt3 sprockets, and power grip htd timing pulleys today.