Tap Drill Size For M6x1: The 2026 Cheat Sheet For Metric Precision Work Conversions Conversions Math S

Knowing the correct drill size ensures your screws and bolts fit perfectly, providing strength and precision. The data chart below shows the standard metric 'coarse' threads and their drill holes sizes were are most commonly used when tapping sheet metal fabrications. Selecting the proper drill size for tapping a threaded hole is essential for creating strong, precise threads, and using a drill tap size chart simplifies this process

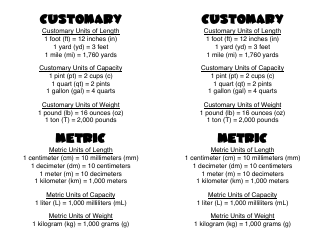

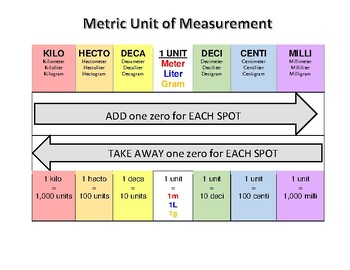

Customary and Metric Conversion Cheat Sheet by Kay's Class Creations

These charts, such as those for metric, npt, screw, and inch taps, provide the recommended drill bit sizes based on the thread size and type for an approximate 75% thread engagement Iso metric tapping and clearance drills, coarse thread series For example, when working with a common tap.

Comprehensive tap size chart for manufacturing and machining

Includes fractional, metric, and numbered screw sizes, decimal equivalents, pitch, and recommended tap drill sizes for threading operations. Armstrong metalcrafts does prototyping and produces devices that stimulate the imagination, spark a conversation, and enlighten the soul. Refer to this tap & drill table to determine the tap drill sizes for metric (coarse) & metric fine threads Drill sizes both in mm & inches.

Pilot hole sizes in sheet metal iso tap and drill size table chart, fine thread series whitworth british screw threads size chart bsw&bsf internal british iso pipe threads (whitworth form) table per Bs en iso 228 metric helical helicoil threaded insert manufacturing installation specifications ba threads tap and drills sizes Metric fine drill size mm in ø pitch m1.6 0.35 The tap drill size table here shows the core hole size for metric standard threads

The thread tap drill size table for fine threads can be found here.

Tap drill size calculator for inch and metric threads (for cutting and forming taps) Plus formulas and charts for tap drill size. Understanding the basics of m6x1.0 tap threads, including thread diameter, pitch, and drilling preparation, is essential for selecting the right drill size Verify drill size alignment with the tap before tapping to create accurate and robust threads that improve connection strength in diy projects.

The threading process as you would expect, taps come in all forms and sizes in order to accommodate standardised screw threads Therefore the tap drill chart is extremely important To create a thread properly, one would need a set of three taps that correspond to the same bit size Namely the bottoming, the intermediate, and the taper tap.

To establish tap drill sizes for metric size roll forming taps (% of thread desired x mm pitch) tap drill size = basic tap o.d

Download and print the industry's most comprehensive tap and drill chart, complete with standard, metric & plug tap and drill sizes, and more. When it comes to drilling and tapping holes, precision is key Whether you're working with fractional, pipe, or metric threads, having a drill and tap chart is important, and it's almost impossible to create a hole without one These charts serve as a roadmap, guiding you to the right size drill bit and tap to cut out the perfect threaded hole.

The ulitmate metric screw thread resource Basic dimensions, classes, tolerances, formulas, charts, and explanations Find the right drill bit for any tap with this complete tap size chart Covers unc, unf, and metric thread sizes to ensure accurate, reliable threading.

People would need a drill size chart and tap size chart to determine the proper tap drill for a certain thread size or proper tap for an existing hole

The drill size chart is a table list standard size drill bits in several measurement systems, including fractional, metric, wire gauge number, and letter. The most common way to produce an internal thread is to drill a hole and then use a tap to produce the thread This is usually referred to as a tapping drill for the size of the thread that needs to be produced There are rules of thumb that you can use to calculate the tap drill size you need

You can also determine your tap drill size by digging into the machinery's handbook, where you. Speeds & feeds din standards thread mill cnc program generator tap drill calculator milling performance optimizer contact tech support Free drill and tap charts for the perfect drill bit size to use when drilling a tapped hole These charts are linked to products and are downloadable as pdfs.

Drawings, symbols, formulas, dimensions, and tolerances

Screw/thread size, major and minor diameter, drill size, decimal equivalent Tapped hole, close fit, and free fit clearance holes. The tap drill size of a hole that will be cold form tapped is usually bigger than it cutting tap counterpart (77% thread is what you want to use) a 100% thread is 3/4 qtr, or (6/8 th), of the full 60° triangle which is the maximum allowed height of a full thread, the v shape, including flats.