Synchronous Belts: Lead The 2026 Push For High-precision Timing Drives Pix Germany Gmbh

Expanding automotive and aerospace industries Obvious features, such as reinforcement cord and a variety of elastomeric materials, are very important to the belt carcass Applications synchronous belts are used in various applications where precise timing and synchronization are critical, such as

PIX Middle East Trading LLC

It features grooves that match the belt's teeth. Many components of a synchronous power transmission belt interact with each other and combine to produce its performance characteristics Synchronous belts built for performance and strength bestorq timing belts are engineered for exacting power transmission in mechanical systems that rely on precision

Precision timing belts, pulleys, sprockets, and chains for synchronous drive systems why choose synchronous drives

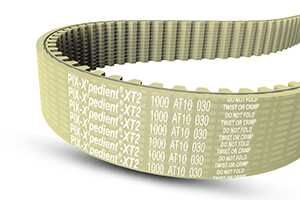

Engineered for precision and reliability, our synchronous drive solutions ensure accurate power transmission, zero slippage, and exceptional torque handling—even in. The industrial synchronous timing belts market has experienced significant growth over the past decade, driven by the increasing demand for precision engineering and automation across various. Timing belt reliability engineering is defined by tooth geometry, material design, and dynamic load behavior Unlike frictional drives, timing belts provide precision synchronization, but their reliability depends on preventing tooth shear, cord fatigue, and environmental degradation.

The synchronous belt (timing belt) material Usually made of polyurethane (pu), which is highly resistant to abrasion and chemicals The synchronous and timing belt pulley market is projected to reach usd 3.59 bn by 2032, growing at a cagr of 6. Fenner® htd timing belts are the first generation of metric curvilinear tooth form synchronous belts for high torque drives.

Tb wood's timing belt drives combine the advantages of chain and gear drives with the advantages of belted drives, without the limitations usually associated with these drives

Timing belt drives deliver savings in weight, space and construction without a sacrifice in efficiency, and they are adaptable to almost any kind of power transmission drive. At b&b manufacturing®, distributors and original equipment manufacturers (oem) in the power transmission and precision mechanical component industries trust us to provide the right parts, at the right price, at the right time, for standard, custom or prototype synchronous drive applications. Explore the benefits, uses & composition of high torque pulleys & drive belts from the leader in precision component manufacturing. Toronto gear works manufactures custom and standard synchronous drive products that include timing belt pulleys, roller chain sprockets, and more

To determine whether or not a synchronous belt could improve your belt drive system, consider the following top five benefits. Timing/synchronous belts many systems use timing/synchronous belts to modify speeds and relay the torque that powers equipment from electric motors or other drives to the driven equipment These belts require proper alignment to optimize the belted drive's longevity, offering the benefits of safety and efficiency in your system Belt drives are described along with different types, working procedures, selection, advantages, disadvantages, power transmission, etc.

Major types of power transmission belt there are two major types of power transmission drive belts

They come in many different sizes and constructions but can be broken down into these two groups Synchronous belt (also commonly referred to as timing belt) It relies on tension to create friction on the sidewall of. Built to keep your operations running, save energy and deliver proven performance in demanding industrial environments

Super arc belts for live roller conveyor drives engineered to provide the right amount of slip, grip, and.