Safety Inspectors Debate Ul 698a Interpretation For Remote Oil Rigs Prevention Is Better Inspire

Understanding their applications and requirements is essential for engineers, electricians, and facility managers working in industries such as oil and gas, chemical processing, and manufacturing This article explains how these complex machines operate, the different types available, and the challenges they face. Ul 698a is the underwriters laboratories (ul) standard for safety for industrial control panels relating to hazardous locations.

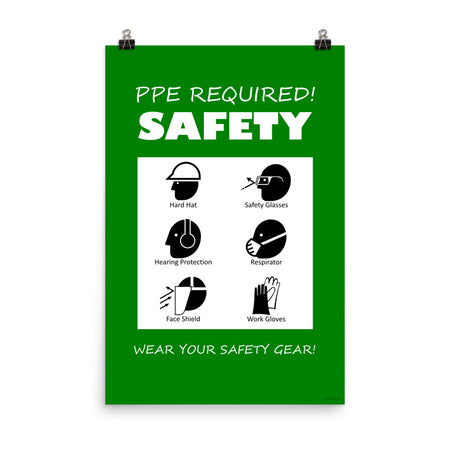

Prevention is Better – Inspire Safety

Ul698a certification is an official approval from ul, stating that an industrial control panel is safely designed and built to control equipment in hazardous locations Oil drilling rigs are essential for extracting the oil that powers our world It proves that the panel meets strict safety standards for preventing fires, explosions, or ignition risks caused by faults, electrical failures, or incorrect installations.

The path to ul 698a certification achieving ul 698a certification involves a rigorous process of design, testing, and inspection

Manufacturers must submit their control panels to ul for evaluation This includes thorough testing in simulated hazardous environments to verify that the panel will perform safely under extreme conditions. Ul698a is a safety standard for industrial control panels (icps) specifically related to applications in hazardous locations The standard is published by underwriters laboratories (ul), a global safety certification organization that creates many of the most important regulatory standards for the electrical, engineering, and construction industries.

This revision of ansi/ul 698a dated january 17, 2019, is issued to include an editorial correction to the separation by distance requirement Text that has been changed in any manner or impacted by ul's electronic publishing system is marked with a vertical line in the margin. Ul 698a industrial control panels relating to hazardous (classified) locations ul standard edition 4 published date August 21, 2018 last revision

November 04, 2022 ansi approved

The safety of oil rig operations in the u.s Is heavily dependent on a stringent regulatory framework, primarily enforced by the bureau of safety and environmental enforcement (bsee). White paper going beyond ul 508a for safety Understanding when icps need to comply with ul 698a no matter what industry you are working in, safe process control operations are essential to protect your personnel and control system equipment.

When zone 0 and zone 1 aex hazardous (classified) locations are the intended areas Every process control panel that integrated controls, inc Manufactures, is ul approved and nema rated A 698 rating approves the panel to be in a hazardous area.

Occupational safety and health for oil and gas well drilling and servicing operations 1 scope 1.1 coverage the purpose of this document is to recommend practices and procedures for promoting and maintaining safe and healthy working conditions for personnel in drilling and well servicing operations.

Learn about key oil rig safety hazards in our complete guide Discover important measures and technology to improve oil drilling safety and operations. Ul solutions is a global independent safety science company with more than a century of expertise innovating safety solutions. In this informative video, we'll take a closer look at the safety inspections that take place on oil rigs and their importance in maintaining a secure working environment.

Mciver engineering & controls designs and manufactures ul 698a certified control panels for hazardous environments Built to nrbx and nnny standards, our panels deliver safety, compliance, and reliable performance across industries where protection is critical. Effective toolbox talks (tbts) help prevent accidents by reinforcing safety protocols Below are 30 critical safety topics for oil and gas workers, each with what to explain and how to explain for maximum impact.

Learn safety and risk management strategies in the oil and gas industry to reduce hazards, improve compliance, and boost workplace safety.

Now you can download workover & drilling rig inspection checklist for onshore and offshore jack up rigs according to api & osha standards. Keeping a drilling or workover rig operating at a top level of performance requires not only a dedicated robust maintenance program but regular checkups to… The drilling industry is rife with the potential for accidents In fact, it's one of the most hazardous occupations around

Crush injuries, slips, falls, and fires are just a few of the top hazards that can occur on oil rigs That's why prevention is key, and worker safety remains paramount in the oil industry Safety mats for rig floor and stairs falls from 100 feet or more are not. The oil rig safety inspection app allows teams to perform complete inspections of rigs to ensure safety standards are met

Inspectors can capture photos, videos, and other relevant data, then store it securely in the cloud for review and analysis.

The ul 508a industrial control panel shop program is a part of ul's general coverage programs, which offer control panel manufacturers flexibility to apply ul certification marks to a wide range of industrial control panel designs. We'll walk you through the basic guidelines and considerations for the inspection frequency of onshore and offshore oil rigging equipment.