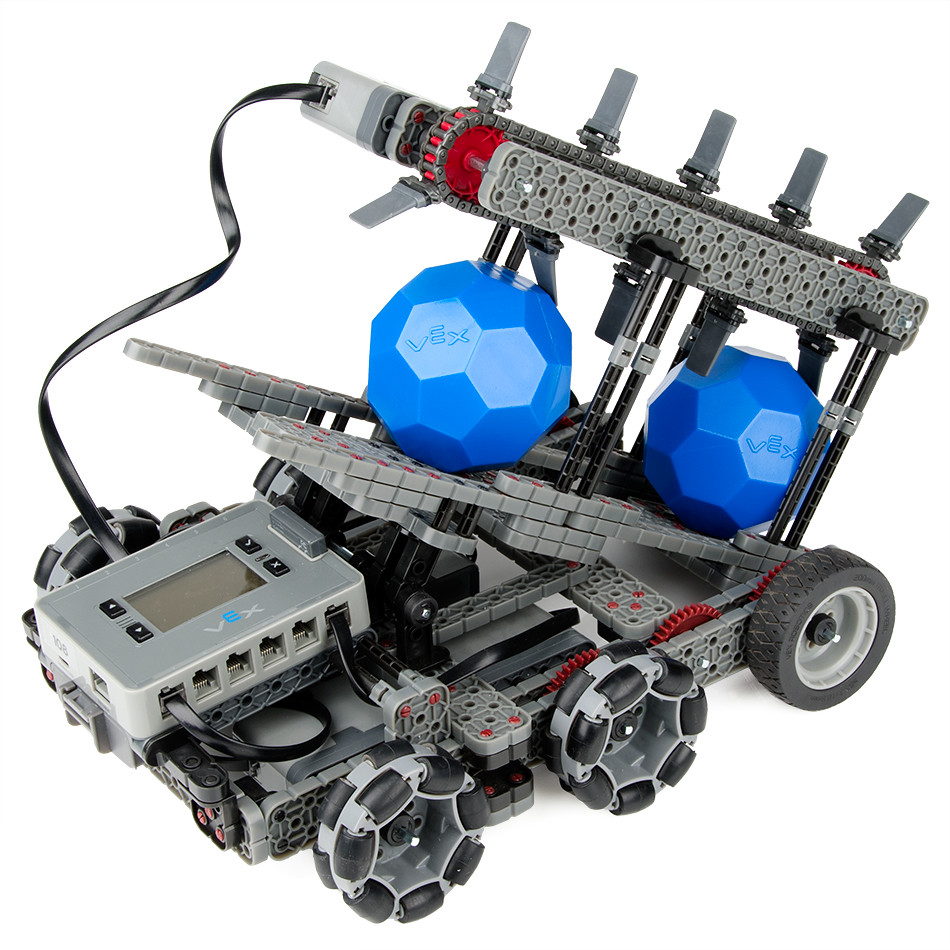

Robotics Experts Debate Linear Motion Components Friction In Vacuum Vex Iq Demo Robots & Projects Vex Flickr

The travel of the stage was specified to be several hundreds of millimeters, in a vacuum. These guides use circulating ball bearings or rollers running in tracks to allow smooth, precise sliding movement with minimal friction. Vacuum applications are common in the manufacturing of semiconductors, liquid crystal and plasma displays, fiber optics, and aerospace components, where linear motion systems are used for the positioning, handling, and alignment of critical equipment

VEX IQ Demo Robots & Projects | VEX Robotics | Flickr

Although vacuum applications are often likened to cleanroom applications, in the category of special environments, there is a critical. For controlled linear motion, miniature linear guides (also called linear motion rolling guides or slide rails) are ideal Many vacuum processes in research and industrial production require the movement of samples or components in the evacuated area

This can be linear position changes in the orientation of the three spatial axes and the revolution around the axis, as a single movement or as combinations of movement types among each other.

In this article, we'll explore the importance of linear motion in robotics, how linear actuators and guides enhance robot performance, and present case studies showcasing the application of linear motion systems in various robotic contexts. The friction model may then utilize both the dynamic robot state and additional information encoded in the latent state to evaluate the friction torque We cast this stochastic and partially unsupervised identification problem as a standard probabilistic representation learning problem. The active phase of the robot dynamics may include both forward motion and minor backward motion, or forward motion exclusively

Extensive numerical studies are conducted using two friction models The numerical solutions to the dynamic problem are analyzed with regard to the total displacement and the average velocity per period of excitation. This is where linear system theory (lst) becomes the backbone of modern robotics While the real world is inherently nonlinear—fraught with friction, air resistance, and complex geometry—the application of linear approximation and control theory provides the essential framework for stability, efficiency, and reliability in robotic design.

A linear motion track system allows devices and machine components to move in a straight line with very little friction

The system includes a track or rail and a moving carriage or slide that glides smoothly along the path. Macron dynamics is a manufacturer of linear and mechanical motion components and systems, providing automation solutions to companies around the globe. Linear motion relies on components like linear bearings and rails to enable smooth and precise movement in machinery across different industries and applications. Unlike rotary drives, linear drives are differentiated by what moves and how far it moves, rather than the sealing mechanism.

Linear bearings for robotics enable smooth, precise, and durable motion in automation Explore types, applications, and tips for reliable robotic systems. High precision custom gears transmit torque and motion with minimal backlash and high positional accuracy High precision bearings support rotating or linear motion while reducing friction, vibration, and wear.

Linear robots are versatile, flexible machines that enable new levels of productivity in manufacturing

Learn how they work as well as their pros & cons. Explore how linear motion systems enhance robotic automation with precision, speed, and reliability Alongside bearings, which reduce friction, motors, and gears, the average humanoid robot relies on dozens of screws—key components that convert the rotational motion produced by a motor into. Robotics in automotive manufacturing rely on precise linear movement for welding, painting, and part placement.

At bearings direct, we offer a wide range of linear bearings, linear rails, and motion systems components that are perfect for robotics enthusiasts Whether you're building your first 3d printer or a complex automated system, we have the quality, affordable parts you need to ensure your project moves with the precision and reliability it.