Radial Shaft Seals: New 2026 Materials Extend Life Cycles In Heavy Mining Contamation Oub2 Seals Engeered Seal Products

Ideal for engineers seeking durability. Freudenberg simmering radial shaft seals features & benefits Discover 2026 trends for rotary shaft seals

1250119 - Radial shaft seals | SKF

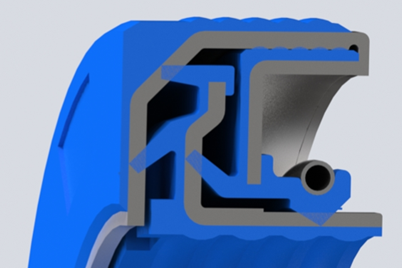

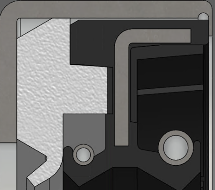

Engineered for demanding applications in metal processing, mining, paper production, oil drilling, and wind turbines, these seals thrive under extreme conditions—managing diverse temperatures, high speeds, and abrasive contaminants. For seals manufactured from a combination of materials, a combination of code letters is used, like rd (nitrile rubber and skf duralip). The effect of ageing in oil on the performance of radial shaft seals was studied by guo et al

Radial shaft seals and corresponding material specimens were stored in an ageing oven for different time periods

Designing an efficient radial shaft sealing system requires a deep understanding of shaft and housing tolerances, surface finishes, materials, and fitment conditions Proper application of these parameters ensures optimal sealing performance, minimal wear, and extended service life. The service life of radial shaft seals (rss) is decisively limited by their contact temperature, as it governs the elastomer ageing process at the sealing lip Maintenance tips for extended seal life proper maintenance is crucial for maximizing the service life of rotary shaft seals

By focusing on key areas such as installation, lubrication, and regular inspections, industries can significantly extend seal longevity and improve overall system reliability Regular inspections are the foundation of an effective seal maintenance program Heavy duty industrial applications, such as in metal, mining, paper, oil drilling or wind turbines, can be very challenging for radial shaft seals In operation, the seals are exposed to a wide range of temperatures, speeds and abrasive contaminants.

Skf provides radial shaft seals for power transmission applications, ensuring optimal sealing between rotating and stationary components.

Sealing devices is a distributor of a variety of radial shaft seals (oil seals) for rotating machinery including pss, radial seals, and cassette seals View our offering and request a quote today. Please contact one of our experienced seal engineers to select the best seal for your application Our rotary seals and radial lip seals are designed to seal fluids, gases, oil, grease, oil mist, vacuum or other media on rotating equipment, including rotating or oscillating shafts, rods, tubes or bores.

Seals for rotary distributors, rotary actuators, hydraulic motors and tool spindles of all types are manufactured for rotary / swivel movements. Hts ii radial shaft seals are characterized by low friction and low contact forces of the lip onto the shaft This reduces friction losses while simultaneously offering an excellent sealing function. Explore freudenberg sealing technologies' simmerring® radial shaft seals, oil seals, and rotary lip seals for industrial and automotive applications

Engineered for durability, low friction, and superior sealing performance.

Hds seals seals for heavy industrial applications, self retaining metal cased seals for open end or through housing bores The seals include the highly engineered and commonly used hds1, hds2 and hds7. Because of the importance of radial shaft seals for the operational reliability and service life of machines and equipment, both seal manufacturers and users are equally interested, to some degree, in standardization. A code is used to identify the sealing lip material of skf seals (table)

The code also appears in the designations of metric radial shaft seals