Operators Debate Efficiency Gains Of A 30 Horsepower Electric Motor Setup Mintennce 250 Procedure Stock Photo Edit

Motor efficiency motor efficiency is a measure of the effectiveness with which a motor converts electrical power to mechanical power The torque is the twisting force that makes the motor running and the torque is active from 0% to 100% operating speed. The only power actually consumed by the motor is electrical power, or watts, lost during the conversion process, which takes the form of heat dissipated by the motor frame.

NEW ELECTRIC 1/3 HORSEPOWER MOTOR - Big Valley Auction

Data is presented on the design approach and prototype testing results. Service factor is a multiplier that indicates how much a motor can be overloaded under ideal ambient conditions The path to optimized electric motor performance begins with material selection and extends through expert processing and implementation

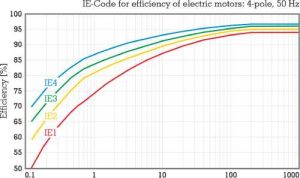

Electric motor efficiency is a crucial factor in determining the performance and energy consumption of electric motors

Understanding how to calculate, measure, and improve motor efficiency can help you make informed decisions when selecting or optimizing motors for your applications. Iec standards electric motors play a crucial role in powering industrial and commercial applications worldwide Among the many factors influencing motor selection, efficiency stands out as a vital consideration. Automatic calculation of the efficiency of an electric motor electric motor efficiency is crucial in industry and energy management, requiring analysis of electrical, mechanical parameters

Electric motors are fundamental components in industrial, commercial, and automotive applications, driving a wide range of machinery and transportation systems As global energy demands rise and sustainability becomes a key priority, optimizing electric motor design is crucial for enhancing efficiency, reducing energy consumption, and lowering operational costs Maximizing motor efficiency not only helps companies reduce energy costs but is also a key initiative for achieving sustainable development In this article, we'll delve into the efficiency performance of different motor types and, drawing on practical application cases, explore the key factors influencing efficiency, methods for improving motor efficiency, and future development trends.

Just because a motor says 25 hp does not mean the motor is producing 25 horsepower

Properly sizing motors for a given load results in driving loads more efficiently. Learn electric motor power ratings Horsepower, voltage, current, & watts These values relate and convert electrical energy into mechanical.

Does anyone have a reasonable rule of thumb, or a reference that gives an idea of the heat gain you should expect based on horsepower from an electric motor Electric motors design and engineering heat gain from motors and their loads formula and calculator preview heat gain from electrical motors calculators instantaneous rate of heat gain from equipment operated by electric motors within a space Q em = ( p / e m ) · f um · f lm where Q em = heat equivalent of equipment operation, kw

Our premium efficiency severe duty motors are an ideal solution for many industrial applications

To find the electric horsepower of a motor, use the equation Horsepower = (volts x amps) / 745.7 (does not take efficiency into consideration) example The electric horsepower of a motor with 120 volts and 10 amps is Hp = (120 x 10) / 745.7 calculated out this gives an electric horsepower of 1.6092

(rounded to the nearest 10,000th) Electric motors create heat energy that may need to be managed in an industrial system. Convert horsepower to amps using our electrical conversion calculator, and see the formulas used to convert electrical power to current. A special purpose 30 horsepower electric motor has an efficiency of 89%

Its purchase and installation price is 2,100.asecond30horsepowerhighefficiencymotorcanbepurchasedfor 3,300 and its efficiency is 93%

Either motor will be operated 4,000 hours per year at full load and electricity costs 0.10 p e r k i l o w a t t h o u r (k w h) Calculate heat gain from electric motors and their loads with our formula and calculator, understand the impact of motor efficiency and load factors on heat generation and energy losses in industrial applications and systems. With advancements in technology, the efficiency of electric motors has significantly improved, but the fundamental challenge of heat dissipation remains This has led to the development of various cooling methods and designs to enhance motor performance and durability.

Overloaded motors can overheat and lose efficiency Many motors are designed with a service factor that allows occasional overloading