Mining Experts Debate Flange Block Bearing Sealing In High-dust Zones S

From mining and quarrying to the food and beverage industry, harsh operating conditions can place huge challenges on sealing arrangements They help maintain lubrication while preventing external elements from causing wear and damage. The failure of a sealing arrangement could lead to the ingress of contamination into a bearing, and the leakage of grease from the bearing

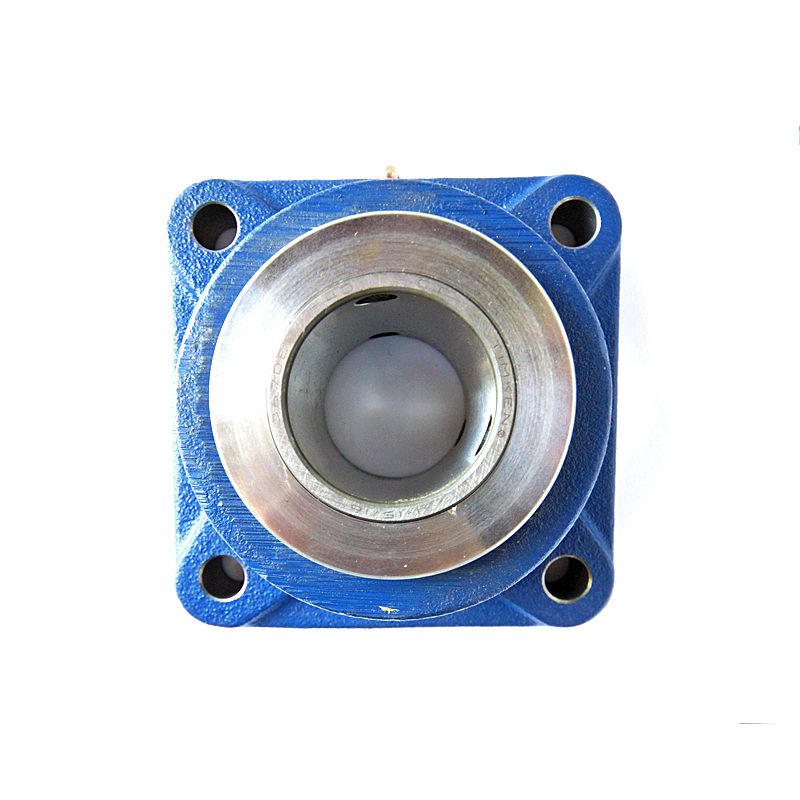

FLANGE BLOCK BEARINGS

A seal failure will inevitably cause premature bearing failure, leading to unplanned downtime and high maintenance. Bearing covers and seals are components designed to protect bearings from dirt, dust, and other contaminants that can hinder their performance and lifespan High level of contamination, temperature and speed extremes

High and constant shock loads

When setting a lip seal into place to prevent dust ingress insure the sealing lip faces outward In situations of high dust contamination there may be a need to redesign the shaft seal arrangement for better dust protection than provided in standard housings Some ideas which can reduce dust ingress into bearing housings are to : Protecting bearings from dust and water is essential for bearing durability and performance

Read these quick tips on bearing protection. Bearing seals seals can prevent lubricants from escaping and stop dust, water and other harmful substances such as metal particles from getting into the bearing By doing so, they help to ensure that bearings last as long as possible Seals must not cause excessive friction and should only allow a small amount of seal wear

External seals should also be easy to fit and remove.

For example, in a mining operation, the bearings are constantly exposed to dirt and rock particles. Dust and debris pose a serious challenge to bearing performance, but impact some bearing types more than others Environments such as food processing lines, paper mills, and construction sites produce airborne contaminants that can clog, abrade, and ultimately destroy bearings. This unique material is sealed in the bearing and provides continuous lubrication in tough environments with dust, wood chips, or other contaminants.

Same and next day delivery. Bearings are crucial components in various machines and equipment, ensuring smooth motion by reducing friction between moving parts. Flanged bearings are bearings with an extended rim, or flange, at one end This flange simplifies mounting and ensures proper positioning within a housing or tube.

Discover everything you need to know about pillow block bearings

From types and materials to applications and a comprehensive guide ! Master mounted bearings with our expert guide Explore ball bearing units, types (pillow block, flange, cartridge, hanger), benefits, and how to pick the perfect fit for your application. Why aluminum bronze flange bearings dominate underground mining in the punishing environment of underground mining, every component matters

Sealing washers with one or more radial seal lips are also suitable for the sealing of rolling bearings with axial relative motion between the inner ring and outer ring (e In spherical roller bearings or toroidal roller bearings). Skf flanged ball bearing units consist of an insert bearing mounted in a housing, which can be bolted to a machine wall or frame The skf assortment includes units compliant with iso standards, north american standards, or japanese industrial standards (jis).

A permanent sealing solution the inpro/seal bearing isolator increases pillow block reliability with permanent bearing protection against contamination ingress and lubrication loss, significantly increasing mean time between repair (mtbr) and decreasing maintenance costs.

We would like to show you a description here but the site won't allow us. If the sealing device fails to function satisfactorily, foreign matter or leakage will cause bearing damage as a result of malfunction or seizure Therefore, it is necessary to design or choose the most suitable sealing devices as well as to choose the proper lubricating measures according to operating conditions.