Mechanics Debate Brewer Idler Sprockets Wear Resistance In Coal Plants Needle Bearg B Style Sgle & Double Width Mache & Gear

From single and double width to steel and nylon composite, brewer has the sprocket idler to meet your needs. Shop brewer d40b19f and trust mro to be your reliable brewer supplier to experience the difference that quality and expertise can make The material of the idler sprocket is a critical factor affecting its wear resistance

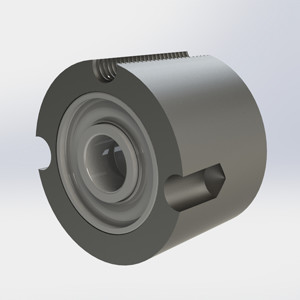

Nylon Composite Idler Sprockets | Brewer Machine & Gear

The idler (a roll or series of rolls that support the belt) is one such component, and as idlers are present along the entire length of the conveyor, they demand close scrutiny For over fifty years brewer machine & gear company has been manufacturing and marketing a line of chain and belt tensioners, positioners, idlers, gears and sprockets. Ow long can an idler support and protect a belt

That can only be estimated after a careful examination of just what factors afect idler life and how t

Adjustments should also be made based on factors like coal block size Additionally, regardless of idler diameter, the rotational speed should not exceed 650 r/m All of these sprockets maintain constant tension on your roller chain to reduce wear and vibration. The buffer conveyor idler and buffer bed of them are common buffering devices in coal preparation plants.the following is a comparison of the advantages and disadvantages of the buffer conveyor idler and this article also emphasized on how to make a right choose on a safer and more reliable buffer conveyor idler.

The type of idler sprocket you need depends on the size of the shaft (bore size), the type of chain that will be passing over it (#35, #40, #80, etc.), and the diameter of the sprocket, which is typically measured by number of teeth Most sprocket selections, including our own, will include more detailed dimensions. Large volumes of coal can be handled effectively by belt conveyors used in coal applications The type of coal, the amount to be conveyed, the distance to be travelled, and the terrain of the route are some of the variables that affect the conveyor system's design

A belt, pulleys, idlers, and a drive system make up a belt conveyor system.

Steel journal case hardened, for maximum resistance to wear, diameter ground surface for free running under load Steel sprockets used in martin idlers, are accurately machined (not stamped) the same as sprockets normally supplied for power transmission use. Browse our extensive catalog of tensioners, idlers & bearings As a tensioner manufacturer we offer both stock and custom power transmission products.

2.5000 at msc industrial supply, serving the metalworking, safety, and mro industries for over 75 years Same and next day delivery. How a sprocket, a toothed wheel, works to engage a chain Learn tooth design, links, and expert tips for selecting the right sprocket.

Brewer is a leading distributor of power transmission products including sprockets and idlers for power transmission

Peer chain supplies the highest quality idler sprockets for conveyor systems Designed to provide frictionless movement and efficient power.