Mechanics Debate Adjustable Vee Belt Reliability In High-torque Drives Comparg And Cha For E Bikes E Bike Commutg

Engineers must therefore analyze every factor that influences belt performance Explore belt drives, their types, design principles, and diverse applications in machinery, automotive, and industrial systems for efficient power transmission. Load capacity, efficiency losses, fatigue mechanisms, and predictive maintenance methods

4 Vee Belt Royalty-Free Images, Stock Photos & Pictures | Shutterstock

Transfer power (torque) from one location to another Belt drives have evolved teeth and are not to be outdone Motor, peddles, engine, windmill, turbine to driven

Conveyor belt, back wheels/ bike, generator rock crusher, dryer

Gear drives have a higher torque capability but are not this flexible or cheap. The shape of the belt creates a wedging action, increasing friction and reducing the chance of slippage, even under high torque or heavy load conditions This means that vee belts can handle the rigorous demands of. Each belt type has unique tension and alignment requirements, and even subtle changes in torque or speed can lead to belt slippage and premature belt failures.

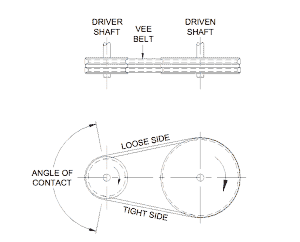

The power transmission rating of a vee belt drive is based on the belts used, the number of belts, the angle of wrap of the belt on the smallest pulley,and the rotational speed of the pulleys. It is now the basic belt for power transmission They provide the best combination of traction, speed of movement, load of the bearings, and long service life Several factors influence the friction, including belt tension, pulley material and size, and the angle of the vee grooves

Fenner transmission belts and pulleys have an enviable worldwide reputation built on consistent performance in the harshest environments

Built using the highest quality materials, with technically advanced production processes, and backed with rigorous quality procedures. Optibelt de méxico s derl decv r.f.c Llc „optibelt power transmission optibelt power transmission india pvt Optibelt power transmission (shanghai) co., ltd

Optibelt gmbh (filiaal belgie) optibelt colombia s.a.s They offer several advantages and, like any technology, have some disadvantages as well. These belts are suitable for light to moderate industrial applications and are known for their durability and reliability Used in tractors and harvesters to drive various attachments

Common in fans and blowers for heating and cooling systems.

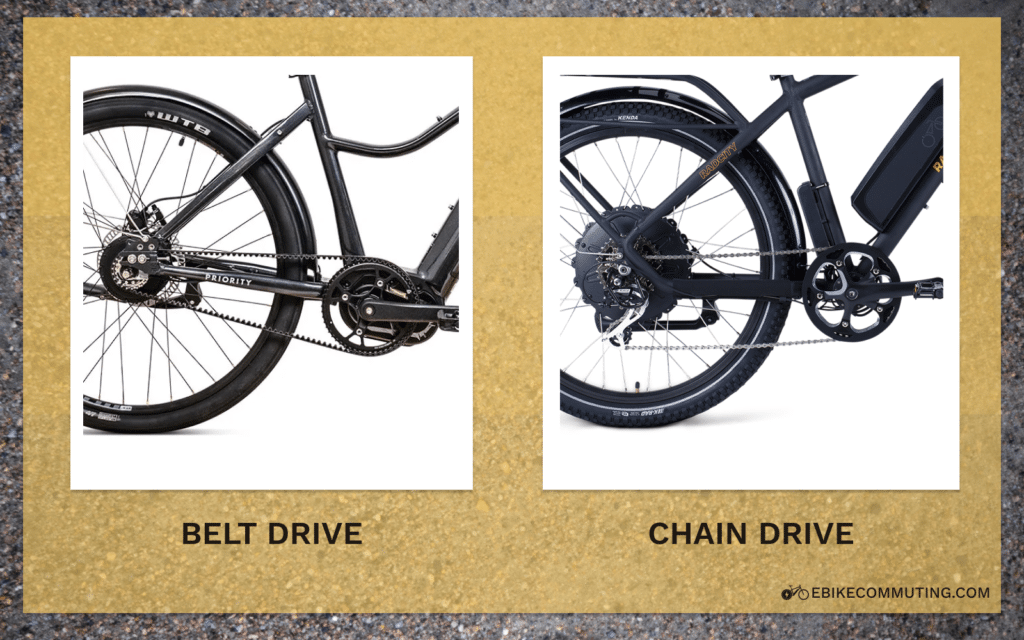

This simple yet effective mechanism makes vee belt pulleys ideal for use in systems where maintaining a constant speed and torque is important Whether in an industrial machine or a car engine, v belt pulleys ensure that the various components work together seamlessly. Learn more about the advantages and disadvantages of belt drives compared to gear drives in this article. The document discusses the differences between belt drives and chain drives, including their designs, applications, and characteristics

For belt drives, other than synchronous drives, the belts will slip in a high overload event providing a certain measure of safety The belts transferring torque by surface friction need to be in tension This results in the need for adjustable shaft centres or using tensioning pulleys types of belt drives note More details and pictures of all belt types below are to be found at the links.

Belts also offer the added feature of acting as a safety fuse in the drive system

In a peak torque or drive blockage situation, the belt (often the least expensive component of the drive) will break, sacrificing itself rather than the breakage of much more expensive components (shafts, etc.) in the system. Belt drives are described along with different types, working procedures, selection, advantages, disadvantages, power transmission, etc. Looking for mechanical drive components, couplings, or conveyor components Dodge products maximize uptime in any application.

![Belt Drives: Types, Slip/Creep [Advantages/Disadvantages] PDF](https://www.theengineerspost.com/wp-content/uploads/2018/08/belt-drives-2-min-300x152.jpg)

![Belt Drives: Types, Slip/Creep [Advantages/Disadvantages] PDF](https://www.theengineerspost.com/wp-content/uploads/2018/08/slip-of-belt-e1533483645481-1.png)