Keyway Hole: 2026 Edm Innovations Make Precision Cutting 50% Faster Knife Microlek Online Store

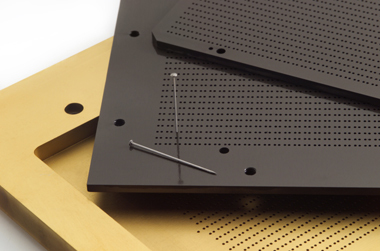

A third type, edm drilling, has emerged for precision holemaking in the smallest sizes, going beyond its use initially as an edm popper for starting holes in hard metals. It examines the historical, cultural, and social transformations that shaped jewish life during this period, emphasizing the challenges and responses of jewish communities across different regions Technological advancements in edm, including automation and faster cutting speeds, enhance productivity while maintaining precision, supporting efficient compliance with complex project demands.

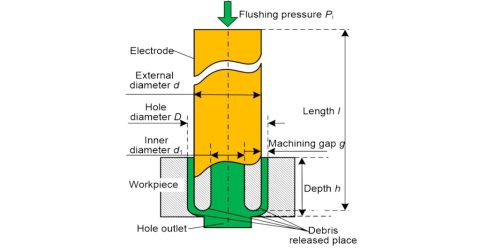

Hole Drilling EDM: Definition & Applications

How edm machine technology works The cambridge history of judaism, volume viii focuses on the modern world from 1815 to 2000, exploring the complexities of jewish modernity through various essays Principles of spark erosion electrical discharge machining (edm) basics and principles edm, short for electrical discharge machining, takes away material through controlled electrical sparks rather than relying on traditional mechanical cutting methods

This differs from standard machining techniques because edm only works with materials that conduct.

Combining milling and edm in one setup slashes lead times for complex geometries. Wire edm is a fantastic cnc machining method for intricate and precise metal cutting We explain how it works, how you can use it, and more. Equipped with a pneumatic intensifier pump that increases drilling speed by up to 50%

Reduces operating costs by up to 40% Programmable digital readouts for precise positioning and automatic hole coordinate calculation Learn how to tackle common pitfalls and unlock the full potential of this advanced. Study with quizlet and memorize flashcards containing terms like true or false

More flat surfaces are produced by the milling process than any other machining process., which of the following best describes the tool and workpiece movement for the milling process

A process involving a rotating work piece. Edm typically works with materials that are electrically conductive, although methods have also been proposed for using edm to machine insulating ceramics Due to its characteristics of no cutting force and high machining accuracy, edm is widely used in processing of amorphous alloys with high hardness, high strength, high brittleness, and high plasticity [99] 4.1 micro electric discharge machining

This occurs because the existing hillside is inherently different than the constructed embankment. Nomenclature of single point cutting tool, geometry, tool signature, functions of tool angles