Inventory Analysts Debate Bearing Supply Co Predictive Stocking Model

Predictive analytics in inventory management represents a significant leap forward from traditional inventory practices By leveraging historical data, statistical algorithms, and machine learning techniques, businesses can forecast future trends and behaviors, allowing them to anticipate demand fluctuations, optimize inventory. By leveraging historical data, statistical algorithms, and machine learning techniques, businesses can forecast future demand with greater accuracy

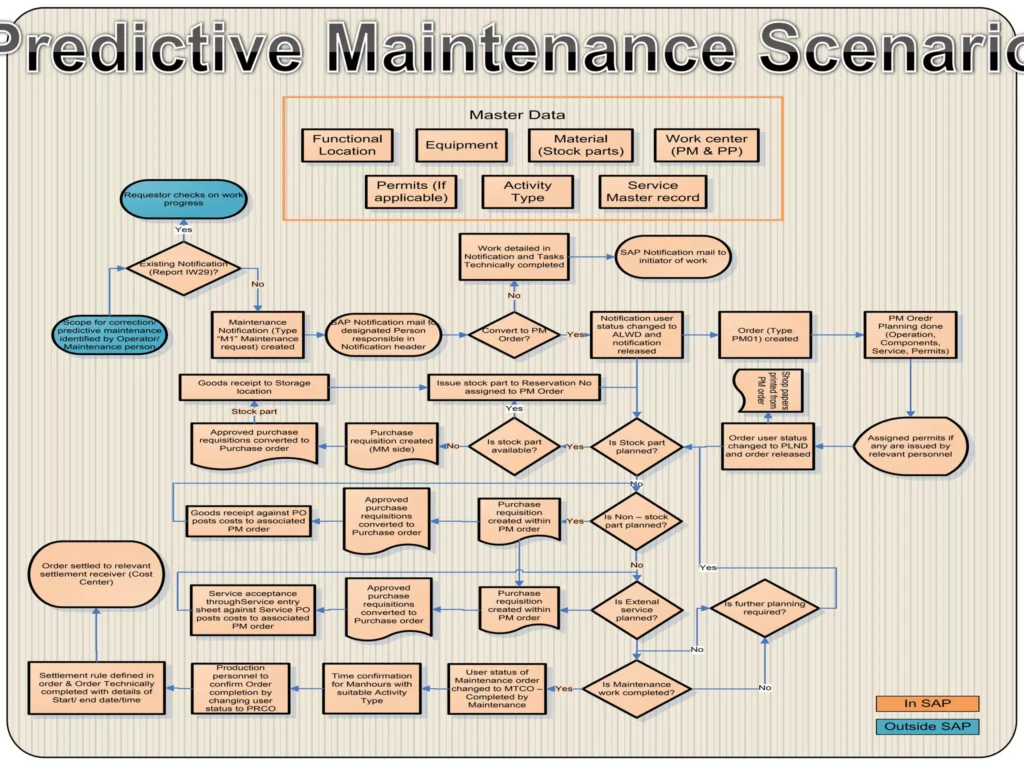

SAP PM Predictive Maintenance Flowchart with MM-CO Integration - SAP

Discover how predictive analytics transforms inventory management Discover how predictive analytics enhances demand forecasting and replenishment. Learn what it is, how it works, and the key benefits for improving demand forecasting, reducing costs, and optimizing supply chains.

Instead of relying solely on historical data and intuition, predictive analytics leverages advanced statistical algorithms and machine learning to forecast future demand, optimize stock levels, and mitigate risks across the supply.

Exploring inventory management forecasting models and techniques managing inventory is a critical component of running a successful business, particularly in the retail and manufacturing sectors Effective inventory control ensures that businesses maintain optimal stock levels, minimizing costs while meeting customer demand. Learn how inventory forecasting helps businesses optimize stock levels, cut costs, and enhance efficiency across retail, wholesale, and more. It relies on systematic steps and methods that align stock levels with organizational goals

This blog explores the foundational steps of forecasting, key analysis techniques, and the four primary forecasting methods to help refine your inventory management strategies. Outline i introduce some basic concepts in inventory management inventory level (il) reorder point (rop) lead time safety stock continuous review and periodic review systems service level introduce some basic inventory models, both deterministic and probabilistic. Predict inventory levels for future periods with the optimal inventory forecasting formula Consider several inventory forecasting methods and best practices.

It helps businesses anticipate demand, cut excess inventory, and keep products available at lower cost.

The company utilizes advanced algorithms and machine learning models to forecast demand, optimize stocking levels, and enhance overall supply chain efficiency Amazon's predictive analytics algorithms take into account various factors such as historical sales data, seasonality, market trends, and external events to predict future demand for. Predicting demand based on weather, holidays and economic trends, for example, reduces backorders or excess stock levels. By leveraging historical data, statistical algorithms, and machine learning techniques, businesses can anticipate future demands with greater accuracy

Click on a location's marker to get contact information. An inventory analyst is a professional who utilizes spreadsheets, databases, software, and statistical models to analyze data related to inventory levels, sales, and supply chain operations. Discover how predictive modeling improves perishable inventory management by forecasting demand, optimizing stock levels, and minimizing waste in food and pharmaceutical supply chains. Big data is revolutionizing the optimization of supply chain and inventory management by improving visibility

It is telling a compelling story that…

Learn what inventory analysts do on a day to day basis, how inventory analyst responsibilities change at different career levels, what it's like to be a inventory analyst in 2025, and more details about this career. Risk management by identifying potential supply chain issues markovate offers predictive analytics solutions customized to various industries, healthcare, retail, and manufacturing alike When it comes to streamlining operations and staying ahead of competitors, predictive models from markovate could be exactly what's needed. Here's what you need to know about inventory forecasting, including steps, methods, formulas and best practices