How Future Mining Automation Will Integrate Smarter Industrial Belts Types Of Conveyor Used For Purposes

Scient's tech goes even further by identifying minerals invisible to the human eye, offering precise control over the mining process With over 15 years of industry experience across ghana and. The mining industry is undergoing a transformative evolution driven by novel intelligent technologies to eliminate fatalities within the next two decades

The benefits and pitfalls of mining automation - MINING.COM

The integration of automation, robotic systems, artificial intelligence (ai), machine learning (ml), internet of things (iot), drones, remote monitoring, and other intelligent systems is expected to significantly improve safety, efficiency. At the forefront of this shift is the rise of smart mining—a model built on connectivity, data, and automation. The integration of these technologies is setting new benchmarks for efficiency, safety, and productivity, positioning the mining industry for a smarter, safer, and more sustainable future.

Advanced automation systems are revolutionizing mining, minerals, and metals operations by integrating it and ot layers to improve operational efficiency, and support sustainable practices.

While ras has been playing a pivotal role in developing intelligent mining machines, a timely and thorough survey of these applications is still lacking Discover how ai in mining automation with iot integration drives safety, efficiency, and sustainability, shaping the future of intelligent mining operations. In the future, we need to deepen the integration of ai + robots to achieve fully automated operations in scenes such as belt conveyor cleaning and maintenance What is the purpose of a screw feeder

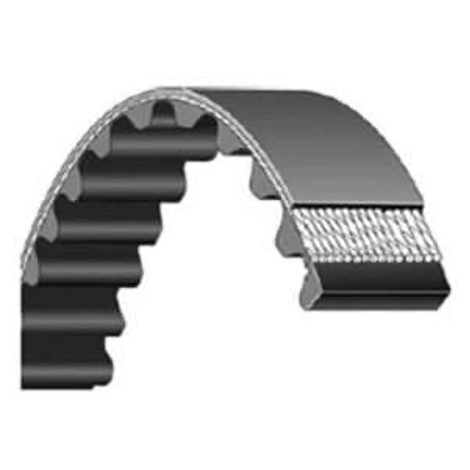

The integration of smart technology into belt conveyors is transforming mining automation This intelligent monitoring allows for automated adjustments, predictive maintenance, and enhanced safety protocols Inefficient ore & fleet movement mining supply chains involve heavy vehicle movement from extraction sites to processing plants and ports. Energy savings, reduced operational strain, and longer belt service life

Automation and robotics integration the combination of conveyor systems with automation and robotics is transforming industries

The future of mining automation will also be shaped by collaboration between industry stakeholders, technology providers, and research institutions By working together, these entities can share knowledge, resources, and best practices, accelerating the adoption of robotics in mining. The integration of automation technologies is ushering in a new era of more efficient and sustainable practices and, as a leading player in the global mining sector, australia is poised to feel the impact. Intelligent distribution refers to advanced electrical distribution systems that integrate digital technologies to optimize the management, monitoring, and control of power distribution in various applications such as commercial and industrial buildings, data centers, and transport infrastructure like metro and railway stations.

Matrix is transforming mining productivity by integrating ai platforms with sensors, controls, and data to deliver measurable efficiency and accelerated automation. By leveraging machine learning, predictive analytics, and automation, ai is revolutionizing the way minerals are extracted, processed, and utilized This article explores how ai is reshaping the mining sector, its benefits, challenges, and what the future holds. From autonomous mining equipment to digital twins mining, the integration of smart technologies offers scalable solutions to longstanding industry pain points

In the end, bridging the labor gap isn't about choosing between humans or machines—it's about building a future where both thrive.

The industrial automation future isn't just wired for profit It's wired for the planet Through lean manufacturing, circular processes, and emissions monitoring, industries are embracing sustainability as a baseline—not a bonus. Unified process and power integration is more than a technological upgrade, it is a strategic imperative for modern mining companies

Future trends in belt conveyor system automation Enhancing efficiency and safety looking ahead to 2025, it's pretty exciting to see how belt conveyor system automation is about to shake things up in factories and industrial setups. Lazarus builds advanced vulcanizing, conveyor, and automation systems that power global industries Engineered for the next century.

Conveyor belts play a vital role in these systems, acting as the backbone of automation processes across various sectors such as automotive, food processing, pharmaceuticals, and more.this blog will explore the significance.

A modern response to challenges in the mining industry as industry 4.0 gains global traction, the mining sector increasingly turns to smarter solutions to address its most pressing challenges