How Aerospace Weight Reduction Is Driven By The Redesigned Bearing Holder Diagram Of Vibration Download Scientific Diagram

Abstract this paper explores the practice of lightweighting in aerospace, which involves reducing a vehicle's weight without compromising its functionality The weight of an aircraft affects everything from takeoff and landing distances, to climb rate, to fuel consumption. Lightweighting is a rapidly advancing field with significant impact on commercial, private, and federal air/spacecraft

Size and Weight Reduction Design Tips — Bearing Choice Can Make a Big

It is a top priority in aerospace research due to its broad benefits, including improved performance, reduced. Weight reduction in an aircraft translates to better performance and fuel efficiency, leading directly to higher profitability and improved environmental sustainability This is crucial in the aerospace industry, where weight reduction is a key factor in improving fuel efficiency and performance.

In the aerospace industry, weight reduction is a critical factor influencing aircraft performance, fuel efficiency, and environmental impact

This article delves into the significance of weight reduction in aerospace component design, exploring strategies, materials, and. In recent years, weight reduction studies using optimization methods have been increasing, and they are widely used in sectors such as aerospace, automotive, and marine While there are many research studies on weight reduction using these methods, weight reduction efforts in aircraft landing gear systems are inadequate Therefore, to address this deficiency, in this study, it is proposed to.

This book covers recent developments and current status of various materials, designs, and manufacturing practices which together contribute towards weight reduction of systems used in defense. In this competitive field, structural engineers are continuously tasked with developing innovative solutions that not only ensure safety and reliability, but also push the boundaries of weight reduction. Inspired by the microstructure of the animal bone, a biomimetic lightweight design is conducted The modern era of aerospace design, driven by environmental concerns and economic pressures, has intensified the focus on weight reduction

Fuel efficiency, driven by rising costs and carbon emission regulations, has made weight optimization a central pillar of aerospace engineering.

Lightweight is a substantial theme in the research and development of aerospace and aeronautical equipment due to its decisive impact on the comprehensive performance and operational efficiency of the equipment Innovative weight reduction strategies for aircraft components tailored for design engineers in aviation and aerospace manufacturing. This drive for efficiency in the aerospace industry is relentless, and its primary focus is often weight reduction Every kilogram saved on an aircraft's structural weight translates directly into tangible benefits over its operational lifespan.

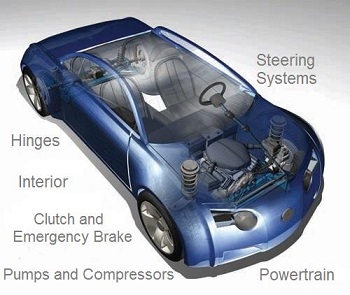

They wanted to redesign it. In several applications, including in the aerospace and automotive sectors, polymer bearings are lighter than their metal equivalents, helping save weight Polymer materials also absorb vibrations and minimize noise in machinery and equipment, improving the overall user experience. A recent breakthrough sentiment growing stronger every day is the integration of 3d printing into aerospace design and manufacturing.

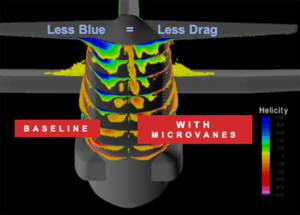

The author attempted to topologically optimize the aerospace component design and tried to manufacture it with ti6al4v alloy using selective laser melting additive manufacturing

The redesigned structure of the aerospace component has 28% weight reduction and with an increased factor of safety by 2 times. Discover advanced lightweight gear materials that improve fuel efficiency and performance in modern aerospace applications. The aerospace engineering field is witnessing an evolution towards lightweight materials driven by the unwavering pursuit of improved performance and efficiency Lightweight materials play a critical role in aerospace structures, and this thorough examination explores their significant influence on mission success, design, and fuel efficiency.

Advanced composites are revolutionizing the aerospace industry, offering unparalleled benefits in weight reduction, strength, and efficiency Despite challenges in cost and recycling, these materials are paving the way for a new era of innovation in aviation and space exploration. The weight reduction carried out via incorporating these bearings contributes significantly to the general performance, gasoline financial system, and performance of aerospace motors How are miba aerospace bearings revolutionizing aviation

How is a miba aerospace bearing constructed

The bearings are made from different materials depending on the specific requirements of the application Miba generally uses a steel backing and a bearing metal such as bronze, aluminium or white metal for hydrodynamic bearings These materials offer an ideal combination of strength and. Weight is a critical design factor in the aerospace industry