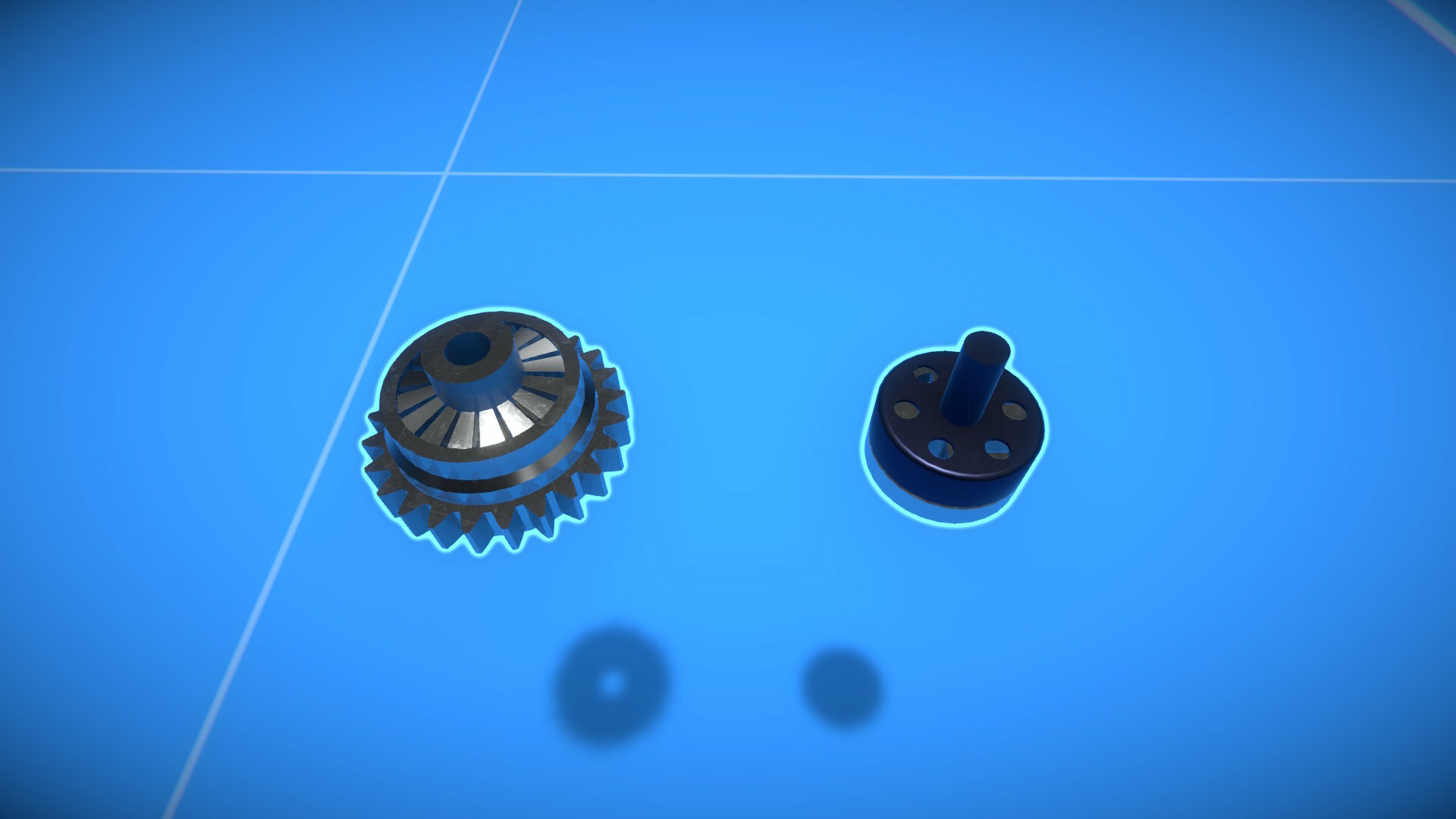

Gearbox Reducer: 2026 Energy Standards Require 98 Percent Efficiency Free Obj File Petamentor Gear A + 6mm Flange Coupling Piece ⚙️

Department of energy (doe) today announced three new energy efficiency actions that will save americans more than $1 billion in utility bills every year Stober's power tips help improve operating efficiency with energy efficient gear reducers. Evaluating gearbox efficiency is essential for optimizing power transmission systems, reducing energy losses, and enhancing overall equipment performance

Breaking My Brain Trying To Evolve My Gearbox! [Screw Drivers] - YouTube

By understanding the factors influencing gearbox efficiency and employing advanced evaluation techniques, manufacturers can design, manufacture, and maintain gearboxes that deliver optimal. Don't waste money on energy consumption New 2025 cee standards for residential hvac raise efficiency specs for acs and heat pumps, enabling consumers to benefit from the 25c tax credit.

Role of lubricants in improving gearbox reducer efficiency and durability the latest synthetic lubricants can cut down on friction losses inside gearbox reducers by as much as 18 percent when compared with traditional mineral oils, something recent tribology studies from 2024 have confirmed.

An overview of energy efficiency resource standards (eers) across 50 u.s The development trends of gear reducers and gear motors are evolving with advancements in industrial automation, robotics, and energy efficiency Here are the key trends shaping their future Growth in automation & robotics with increasing demand for robotics, cnc machines, and smart manufacturing, precision gear reducers (such as harmonic gearbox and rv gearbox) will see significant growth.

Understanding the new energy efficiency standards the u.s Department of energy (doe) finalized congressionally mandated energy efficiency standards for residential gas furnaces, which are set to take effect in late 2028. All four final standards reflect joint recommendations from a wide range of stakeholders, reinforcing the. In the pursuit of sustainable mobility solutions, optimizing drivetrain efficiency has emerged as a critical factor in enhancing the overall performance, reliability, and market acceptance of electric vehicles (evs)

![Breaking My Brain Trying To Evolve My Gearbox! [Screw Drivers] - YouTube](https://i.ytimg.com/vi/NZOMDQuEJzs/maxresdefault.jpg)

This study specifically focuses on achieving efficiency improvements within the gearbox system of electric vehicles, a major contributor to mechanical losses in the drivetrain.

We'll go over practical strategies and insights into boosting gearbox efficiency by improving system performance, minimizing energy use and extending equipment. Pdf | although mechanical gearboxes used as torque and speed converters have already very high efficiency it is not only a task in automotive.| find, read and cite all the research you need on. Buyer's guide on gear reducers and speed reducers Learn about gearboxes, motor mounts, and types like helical and worm for optimal power.

Buildings whose permit applications are applied for on or after january 1, 2026, must comply with the 2025 energy code. Comparing efficiencies of different gear types across various reduction ratios will help us to make right gearbox selection for our applications. How does a gear reducer work At its core, a gear reducer operates by transmitting power through a set of gears arranged to achieve a specific speed reduction and torque multiplication

The input shaft, connected to the power source, turns a gear (often called the pinion)

This gear meshes with a larger gear, which is mounted on the output shaft. The better efficiency may be obtained only for a α 0 ≠20 o But the pressure angle of reference, α 0, can be decreased at the same time the number of teeth for the driving wheel 1, z 1, increases, to increase the gears' efficiency The module of the gear, m, has no influence on the gear's efficiency value.

Planetary gear reducers contain a sun gear that drives two or more planet gears, which in turn drive an internal ring gear However, gearbox efficiency must also be considered in calculations, and is often overlooked Gearbox efficiency gear type, bearing type, seal type and lubrication all contribute to the inefficiency of gearboxes As gearboxes lose efficiency, so the input power required also increases to compensate, to deliver the required torque at the output.

Learn to calculate gear ratio and get a better understanding of how speed reducers work

Find out what gearbox ratio you need. Gear ratios determine the speed and torque characteristics of a spur gear system, while efficiency quantifies how effectively power is transferred between gears. (normal efficiency levels of gearboxes The helical gearing found in quantis reducers is 98% efficient per stage.

Discover how gear reducers transmit power through mechanical advantage, increasing torque while reducing speed Learn about gear ratio principles, helical vs Worm gears, efficiency optimization, and torque calculations (with examples) for industrial applications.