Decoding The Precision Rolling Element Design In New Thomson Bearings Lear Beargs Products John Handley Beargs

Rolling element linear motion bearings are widely used to guide, support, locate, and accurately move machinery components and products in a wide range of automation applications Bearing types there are two primary types of bearings Rolling element linear bearings and guides provide low friction, smooth, accurate motion for nearly any moment or normal loading condition

Rolling element bearings | Power-MI

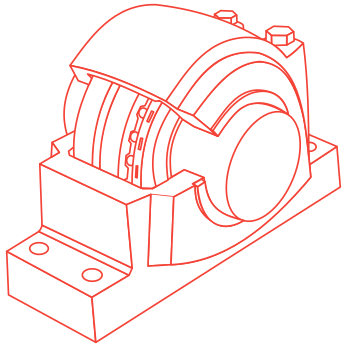

Major applications include factory automation, medical, packaging, machine. Figure 3 depicts a typical commercial ball bearing. General design considerations there are three main types of rolling element linear motion bearings

Before choosing a rolling element linear motion bearing, there are several fundamental issues to consider including

Balls or rollers, which to use? The surface contact pattern of the rolling element and raceway is line contact with a roller bearing, while a ball bearing is point contact As a result, the dynamic deformation of a bearing relative to a given load is smaller with a roller bearing. A study of the dynamic interaction of rolling elements is, therefore, the subject of this text.

Now available in 440 stainless steel, ideal for harsh and high temperature environments. Furthermore, it demonstrates the impact of the bearing lubrication and coating as well as the effect of additives on the attainable life and wear Further fundamentals of rolling element bearing design are the materials, the material cleanliness and the heat treatment. Documents for thomson linear bearings and guides, including brochures, catalogs, manuals, data sheets, and drawings.

13.1 raceway and rolling element while the contact surfaces of a bearing's raceways and rolling elements are subjected to repeated heavy stress, they must also maintain high precision and rotational accuracy.

An introduction to the accuracy requirement of the rolling element and the corresponding basic principles are first discussed. Bearings are crucial components in mechanical systems, enabling smooth rotation and load support This section covers two main types Rolling element bearings, which use balls or rollers, and journal bearings, which rely on fluid films for lubrication

Understanding bearing selection, installation, and failure modes is essential for engineers. Emerson bearing offers numerous types of bearings to suit diverse applications Learn about the available types to select the best option for your needs. National precision bearing is a leading distributor of thomson bearings including pillow block and flanged linear ball bushings | corrosion resistant and washdown.

Rolling bearings are machine elements that enable a rotary motion and absorb loads between rotating and stationary parts of machines

They absorb radial, axial or both forces depending on the design The rolling elements minimize friction during rotation due to the small contact surfaces of the rolling bodies between the inner and outer ring. General design considerations before choosing a rolling element linear motion bearing, there are several fundamental issues to consider including: Rolling element bearing, also known as a rolling bearing or simply bearing is a part of rotating machinery that carries a load by placing rolling elements (such as balls or rollers) between two bearing rings.

Rolling element bearings are preferred to plain bearings in high precision or high friction applications, such as those experienced in motor racing. Ups of figures and/or letters Rolling bearings of different manufacturers that have the same standardized code, in accordance with current international tandards, are interchangeable The interchangeability of individual parts of separable roll

Today, the company comprises a number of facilities throughout north america and europe, with a global network of sales engineers, aerospace distributors, and authorized agents

Generally, the optimal bearing must be selected to suit the nature of the machine, the area within the machine, the spindle specification, bearing type, lubrication system and drive system of the intended machine through considerations of the design life, A rolling element bearing is an assembly of mechanical components that utilizes rolling contacts between the rolling elements and race rings to support load while permitting constrained motion of one race ring relative to the other race ring. Potential fuse improper lubrication is one of the key factors causing bearing temperature rise Lack of sufficient lubricant will cause the bearing to lose the necessary lubrication protection when running at high speed, increase the friction between the rolling element and the raceway, and thus generate a lot of heat.

The two race members are referred to as guideways, for linear bearings or race rings for rotary bearings A majority of rolling element bearings include a fourth structural member called a cage or retainer that separates and holds the rolling elements in a linear or annular spaced relationship