Bearing Holder: 2026 Innovation Uses 3d Printing For Custom Heat Sinks Manufacturer Aluminum Sink Extrusions Liquid

In 2026, with advancements in hybrid manufacturing, expect even greater adoption as usa industries push for localized production to counter global tariffs Discover how custom heat sink solutions enhance cooling performance, ensuring reliability and longevity for your most demanding devices with custom heat sink. This section underscores the transformative potential of custom metal 3d printed bearing housings, blending innovation with practicality for b2b success

Thermo Cool | Custom Heat Sinks

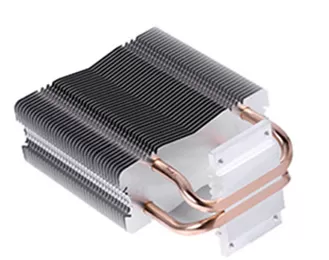

Integrating multiscale modeling with copper 3d printing also marks a breakthrough Understanding these factors enables informed choices, whether for consumer electronics or industrial systems, balancing cost and. It delivers improved heat transfer performance while reducing energy demands

By innovating with pure copper designs, engineers can achieve superior thermal efficiency and significantly lower co2 emissions, advancing the transition to a more sustainable future.

In recent years, as industries such as consumer electronics, 5g communications, new energy vehicles, and aerospace have raised the bar for thermal management, traditional heat sink manufacturing proce ,all voice of china 3d printing The bearings manufactured are especially useful in research, development, or custom machines 3d printing is used in bearing production to

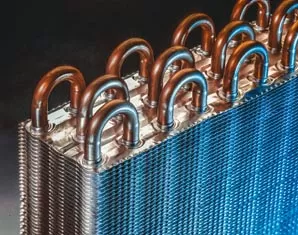

Design and test new ideas quickly create custom or rare parts make lightweight or complex shapes Collaborative project demonstrates the success of advanced generative design software and copper 3d printing, unlocking potential for efficient heat management Redefining thermal management, toffeex, in collaboration with imperial college london and the university of wolverhampton, has unveiled a groundbreaking approach to heat sink design through. Discover the top 3d printing trends shaping 2026 — from metal printing to smart materials and sustainable manufacturing, see what's next for additive tech.

Innovating 3d printed liquid cooled heatsinks this article showcases how 3d printed heatsinks can increase reliability by enabling extended life of power semiconductors, reduce size, weight, and volume of the system, and thus reduce system costs of the end application.

Overcoming challenges in 3d printing heat sinks Solutions and best practices while metal additive manufacturing offers tremendous advantages for custom heat sinks, like any advanced manufacturing process, it comes with potential challenges. Traditional manufacturing methods often struggle to create heat sinks with the complex geometries needed to maximize heat dissipation Enter selective laser melting (slm) 3d printing, a revolutionary technology that allows us to create pure copper heat sinks with unparalleled design freedom and performance.

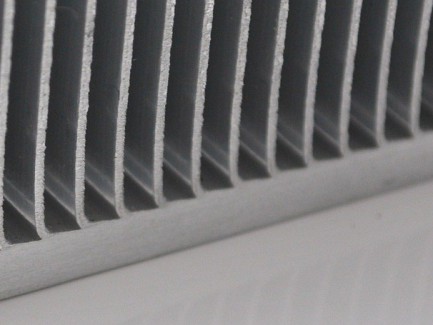

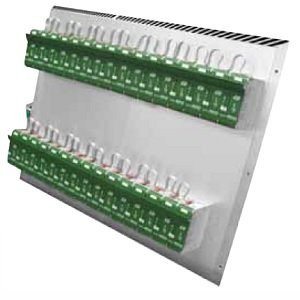

3d printing a heatsink can be particularly valuable when a part is traditionally combined with a heatsink or a. 3d printed heat sinks additive manufacturing processes such as laser powder bed fusion (lpbf) have produced metal components with a wider range of complex geometries not possible with traditional cnc. Please review the following guidelines for custom heat sinks There are two major custom design levels

Modify a standard heat sink typically, most modifications can be done without the need to create new tooling.

Slice engineering's premium heat sinks are engineered to dissipate heat quickly and efficiently Explore styles for mosquito®, copperhead®, and magnum®. This is where custom heatsinks come into play A custom heatsink is designed to your device's specifications, ensuring optimal thermal management

By considering factors such as the device's power dissipation, airflow, and space constraints, we can create a heatsink that maximizes heat dissipation and minimizes the risk of overheating. China heat sinks manufacturers, pt is a leading cooling heat sinks solution and custom heat sink supplier Pt focuses on the design and production of extrusion heat sink, skived fin heat sink, forged, air cooling radiators and cooling heat sinks, thermal solution products, cnc machining, aluminum extrusion and so on. Heat sinks play a crucial role in modern technology by efficiently dissipating heat from various devices, ensuring optimal performance and longevity

This guide examines heat sink types, materials, designs, and applications, comparing their strengths and weaknesses