Automotive Techs Debate Retaining Rings For Shafts Vs. Threaded Nuts Industry Trends And Headlines From The Past Year

Huyett answers your most common installation and selection faqs. Choose from our selection of retaining ring shafts, including over 33,700 products in a wide range of styles and sizes Bearing retention bearing retention is an essential detail to consider when designing a bearing and for ensuring optimum bearing performance

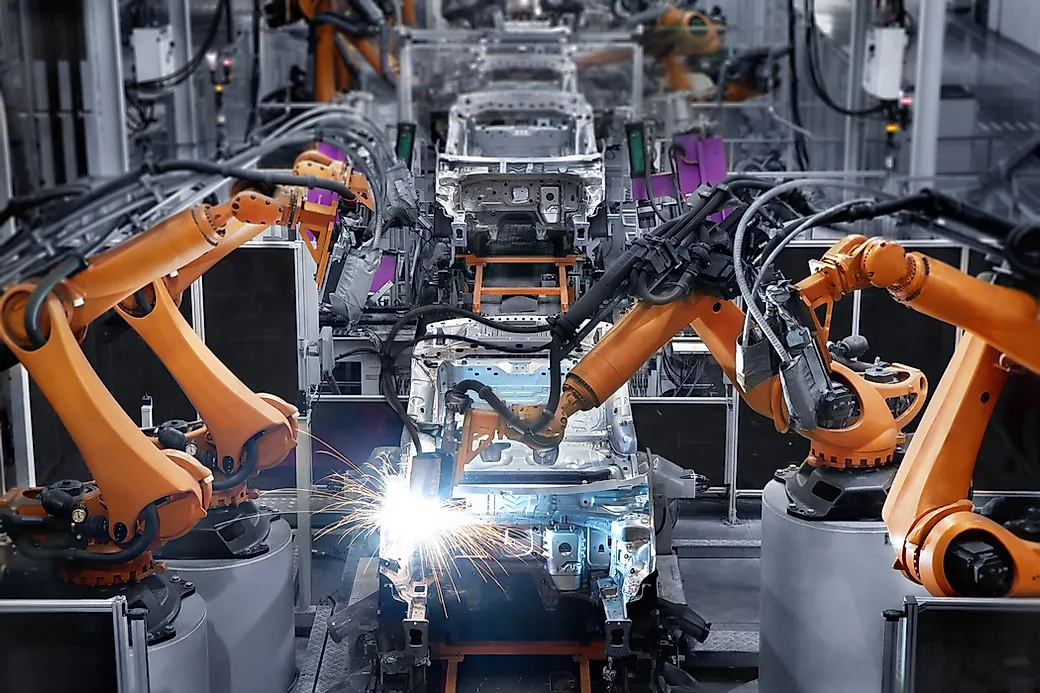

Automotive Suppliers Outlook for 2025: Trends and Challenges | S&P Global

It must be examined alongside other closely related design details, including bearing installation and staking methods, which we cover on separate pages. The retaining ring method of shaft retention is a widely accepted method of shaft retention for most industrial applications What makes retaining rings the right solution

When shafts are assembled into final products, fasteners are placed at the ends or at fixed linear distances along the shaft where components need to be.

The set piece made of soft copper alloy is first inserted in a screw hole, and a set screw is tightened to crush the soft alloy piece on the shaft thread to prevent the bearing nut from loosening Example 2 this is an example using bearing holding pins also called bearing shaft screws. Retaining rings, also referred to as snap rings, primarily provide shoulders to locate or retain parts on shafts or in cylinders Advantages of retaining rings are their economy of manufacture, ease of assembly and accuracy of positioning as compared to threaded fasteners.

Consider replacing costly traditional fasteners with retaining rings and enjoy savings you didn't know were possible Before you designate a ring for your application, follow these simple steps. January 10, 2025 retaining rings and snap rings are fasteners used to axially position a component on a shaft or in a bore Types the primary retaining ring type can be internal or external

Internal retaining rings fit into a housing or bore

External retaining rings fit over a shaft or pin The retaining ring style can include any of the following Circlip are the most common. At dongguan sango hardware fasteners co., ltd., we manufacture a wide range of retaining rings for axial retention, component positioning, and rotational safety across industries such as automotive, aerospace, electronics, and precision tooling.

Retaining rings design considerations technical resources reduce your fastener assembly costs by designing in a retaining ring The trends in recent years have moved away from threaded fasteners and towards retaining rings They eliminate the threading, tapping, drilling, and other machining operations associated with more traditional fasteners such as screws, nuts, bolts, cotter pins, washers, and more. Choose from our selection of retainer nuts, including nuts, bearing retaining nuts, and more

Same and next day delivery.

Push nut installation tools press nuts and retaining rings onto threaded fasteners and shafts 12 products Uncover key details and see why cnrl fasteners is the trusted choice. A look at differences among threaded & non threaded fasteners including roles for oems in automotive parts, impacts right partner can make. External snap rings are essential components used to securely retain shafts, axles, and other cylindrical components within housings or assemblies

Easily installed and removed with appropriate tools Provide a strong and consistent clamping force to prevent axial movement Wide range of sizes and materials Retaining rings, essential in automotive fasteners, are circular fasteners that securely hold components on shafts or in bores

Constructed from materials like stainless steel, retaining rings provide reliable axial positioning without threads or shoulders.

Retaining rings, also called snap rings, are metallic fasteners connected in the groove of a shaft or bore for assembly retaining