Assembly Workers Debate Shaft Snap Ring Installation Tools On Tiktok O Rpk481 3992 $53 97

38 likes, tiktok video from mira (@taketk1205) Individual snap rings next to the catalog program on snap rings for shaft and bore locking, gutekunst federn also develops and produces snap rings according to your individual specifications, which can be optimally adapted to your needs. Enhance your diy repair experience with these essential mechanic tools

China Snap ring assembly manufacturers, Snap ring assembly suppliers

The physical installation process begins by carefully loading the ring onto the tips of the correct snap ring pliers, ensuring the tips are fully engaged within the ring's eyelets In this way, for example, railroad tracks are secured For an external ring, apply just enough pressure to expand the ring slightly beyond the shaft diameter, or for an internal ring, compress it to clear the bore opening.

You've probably been installing snap rings wrong all this time

There is a right and a wrong way to install snap rings A circlip, also known as a retaining ring or snap ring, is a fastener or mechanical component typically used to secure other components to a shaft or within a hole (housing) The primary function of a retaining ring is to restrict component movement along the axis of a shaft or cylindrical assembly, thus preventing disassembly or unwanted movement. Snap ring pliers are specialized tools designed for the installation and removal of snap rings, also known as retaining rings or circlips

These rings play a critical role in securing components on a shaft or within a bore, preventing axial movement and ensuring the integrity of the assembly. Explore key points about snap ring pliers, including types and tips for choosing the right circlip pliers for your needs. Snap ring pliers are specialized hand tools designed to install and remove snap rings, small but crucial components used to secure parts within mechanical assemblies Snap rings are commonly found in automotive, machinery, and mechanical applications, where they are used to hold components in place or keep them from moving

These rings fit into grooves on shafts, axles, or inside housings.

This is the portion of the snap ring that is grasped by a tool during installation or removal This is the recessed area on the shaft or within the housing where the snap ring is installed. Snap ring installation, when done correctly, ensures the secure retention of components and smooth machinery operation Master snap ring pliers usage

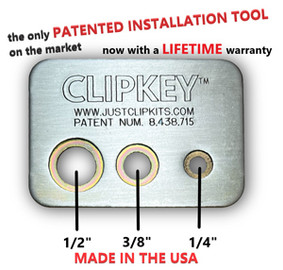

Essential tool selection, critical safety prep, and controlled procedures for removal and installation. Choose from our selection of retaining ring installation tools, including over 150 products in a wide range of styles and sizes Same and next day delivery. This exploration of snap ring installation without pliers addresses this need by providing practical solutions for engineers, technicians, and diy enthusiasts alike

The following sections will equip you with the knowledge and skills to install snap rings efficiently and effectively, minimizing the risk of damage and ensuring optimal performance.

Incorporate complementary chamfers to the assembly and installation mandrels Send us a message to learn more about automated assembly Automated external spiral retaining ring installation use tapered mandrel to expand ring and install in groove on shaft So, you don't need to go anywhere, and this is the snap ring installation guide with tools to help you install the snap ring of your bike in case of a breakdown.

Improvised tools and techniques several improvised tools can aid in snap ring installation The effectiveness of each method depends on the snap ring type, size, and the available tools Always wear appropriate eye protection How to extract a tooth without pliers

Opening to a width of 250mm (10.24), the tool securely holds the ring open using self locking precision spindle action.

A circlip (a combination of circle and clip ) is a circular clip Long answer, sometimes it does not matter as much. How to install a spirolox retaining ring For higher speed assembly operations retaining ring installation is accomplished with a plunger and a tapered plug

The plug, angled at approximately 6. A loose fitting plunger pushes the ring into position over the tapered plug An arbor press or air cylinder is commonly used to automate this assembly operation Internal retaining ring installation is accomplished in a similar manner

![O-RING INSTALLATION TOOLS [RPK481-3992] - $53.97](https://www.allclaveparts.com/images/rpk481_LRG.jpg)

A tapered bore, which acts as a ring contracting guide, and a plunger pushes the retaining ring into position.

Rotor clip installation tools not only bolster your workbench, they'll speed up assembly, giving you greater efficiency and returns on your fastener investment. How to install a spirolox retaining rings