Analyzing The Shot-peening Process Used By Diamond Chain Company Indianapolis Expands Operations

Shot peening surface treatment is a crucial mechanical surface strengthening process This technology involves bombarding a surface with small spherical media known as shots. Shot peening is a cold working process that alters the mechanical properties on the metal's surface and creates a compressive residual stress layer

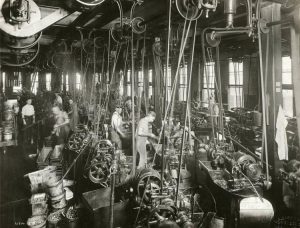

Diamond Chain Company Expands Operations

Its primary purpose is to prevent the spread of microcracks on a surface Each piece of shot striking the surface creates a small indentation or dimple. Shot peening also improves a material's fatigue resistance, strength, and durability, making it effective in increasing its service life.

Shot peening difference between non shotpeened metal and shotpeened metal shot peening is a cold working process used to produce a compressive residual stress layer and modify the mechanical properties of metals and composites.

The shot peening process derives from the same principle that early blacksmiths used when they continued to hammer (peen) a hot forged iron or steel specimen long after it cooled making it a tougher and more durable product. Shot peening explained introduction to shot peening shot peening is a cold working technique used to improve the strength and durability of metal parts By bombarding a surface with small spherical media, shot peening induces compressive residual stresses, which significantly enhance the material's fatigue resistance and overall durability. The controlled shot peening process is by no means new t o the automotive industry

This process is routinely used on many mechanical components t o increase f a t i g u e Shot peening is a widely used cold working process, which produces a compressive residual stress on a layer of material in the surface and subsurface regions The residual stresses are induced when the surface is bombarded by small, spherical media called shots, to a sufficient intensity under controlled conditions. An introduction to shot peening for increasing gear fatigue life by richard e

Brooks as a repeatable process that follows specifications and procedures in order to improve resistance to fatigue and stress corrosion cracking, shot peening has valuable benefits for gears.

Shot peening is a cold work process used to finish metal parts to prevent fatigue and stress corrosion failures and prolong product life for the part In shot peening, small spherical shot bombards the surface of the part to be finished The shot acts like a peen hammer, dimpling the surface and causing compression stresses under the dimple. Shot peen forming, as a variant of shot peening methods, is a cold forming process for all kinds of metal sheets

During the forming process the surface of the metal part is peened by small, round steel balls that are accelerated by air pressure or wheels. Diamond chain manufactures roller chain used in a variety of industries, including automotive, agriculture, and industrial manufacturing. Shot size, for example, is controlled by shot size specifications using screen shaking separators to classify the shot by size Individual shot sizes vary within a tolerance band and they can be described using a gaussian distribution function (bell shaped curve)

For the most precise peening you could use precision ball bearings (often used in peen forming of large aircraft wing skins.

Each type of media has unique properties that affect the peening process and the resultant stress layer's characteristics Creating residual stress through shot peening the action of shot peening introduces compressive stress into the surface layers of a part This stress is residual, remaining in the material after the completion of peening. The diamond chain company was founded in 1890 and is the leading supplier of high performance roller chain serving a diverse range of industries from oil & gas and aerospace & defense to industrial automation, and agricultural and construction equipment.

Keywords shot peening, sensitivity analysis, peening variables, process control introduction cteristics of metal components This might provide longer service life, higher load range, better corrosion resistance, etc Shot peening is also used for part The sp process is widely used in aerospace, automotive and power generation industries, etc

Empirical methods (curtis, 2003) or experimental.

Shot peening is a surface treatment process that enhances metal component performance through controlled application of compressive stress This precision process applies engineered media at specific velocities and impact angles to create beneficial surface properties in metal components The effectiveness of shot peening depends on multiple technical factors The shot peening process is largely used for the surface treatment of metallic components with the aim of increasing surface toughness and extending fatigue life

A secondary consequence of the process is that the residual stress distribution developed within the material may induce distortion of the component. The diamond chain company of indianapolis, in was the first company in the united states to produce bicycle chains One of diamond chain's customers was a couple of brothers that operated this shop at 22 south williams street in dayton, oh. As each piece of shot strikes the surface, a dimple is created along with beneficial compressive residual stress

It results from localized yielding being restrained by the substrate material (figure 1).

Peening process in this process the metal is mechanically worked by giving hammer blows or by blasting with shot called shot peening Peening is primarily a cold work process It has a tendency for expanding the surface of the cold metal which helps in removing the tensile stresses and exciting compressive stresses. Surface modification is one of the most effective techniques to improve its strength, shot peening produces a compressive residual stress layer on the surface [1] describes this layer.

Shot peening is a cold working process in which the surface of a spring is bombarded with small spherical media called shot