Analyzing The Dynamic Balance Required For Modern Belts And Sheaves Classical V Empowering Pumps Equipment

They will operate safely at belt speeds up to 6,500 feet per minute, but at speeds over 5,000 feet per minute and at any speed where vibration is a problem, dynamic balancing is. Belt dressing is used to quiet drive (not enough tension or worn grooves) belts appear to be mismatched if wear is present, replace them with martin sheaves. Dynamic balancing is recommended for speeds equal to or greater than the max rpm for static balancing listed for each sheave

Among Modern Sheaves Wheat Path Trampled Stock Photo 2416158243

If the rpm of a sheave exceeds the max rpm for cast iron listed please consult factory max rpm & dynamic balance chart If motor unbalance is diagnosed, inspect the cooling fan for dirt build up, or broken fan blades. For speeds above this, or when the pulley diameter is less than 7 to 10 times the face width, dynamic balancing is recommended

Before detailing the differences of static vs

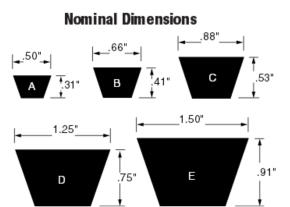

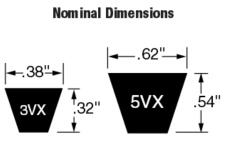

Dynamic, let's first explore balance and its importance to sheaves and the overall drive When an object like a sheave or even the wheel on a car rotates, centrifugal force causes the mass to naturally move away from the axis of rotation Power rating for one belt as a function of size and speed of the smaller pulley belt length (then choose standard size) sizing of sheaves/pulleys (use standard size) Most commercially available sheaves should be limited to 35 m/s belt speed

In conclusion, the dynamic balance requirement for wire rope sheaves is of utmost importance in ensuring the performance, safety, and longevity of the systems in which they are used In conclusion, the dynamic balance of a wire rope crane sheave is a critical factor in the performance, safety, and lifespan of the crane system By understanding what dynamic balance is, why it's important, and how to ensure it, you can make informed decisions when choosing and maintaining your wire rope crane sheaves. Learn how to perform static and dynamic balancing on rotating machinery, from theory to worked examples, using hbk measuring equipment.

The equations using this friction are beyond the scope of this paper but they are based on euler's equation

Some pulleys may require dynamic balancing at speeds less than 6500 fpm Purchase dynamic balance sheaves when the rpm is greater than the maximums determin i 4 High quality sheaves built to mpta (mechanical power transmission association) industry standards. Detecting fan problems using vibration analysis

Fans are subjected to operational forces generated by their operating speed, static pressures and system arrangement These operational forces cause forced vibration and may originate from the rotating parts themselves Unbalanced fan wheels and drive sheaves are examples of forces that cause force and couple unbalance Present day requirements for enhanced reliability of rotating equipment are more critical than ever before, and the demands continue to grow constantly

Some pulleys may require dynamic balancing at speeds l ss than 6500 fpm

Purchase dynamic balance sheaves when the rpm is greater than the maximums deter ne 4 Sheaves act as power transmission masters, enabling speed and torque manipulation through the engagement of belts and ropes Gearboxes, on the other hand, serve as control centers, altering the rotational speed and torque of the power source to suit various applications. Learn how to use variable pitch sheaves in hvac belt drives effectively with this informative video tutorial.

When it comes to sheaves, proper vibration analysis is critical for identifying faults and preventing costly damage to equipment Dynamic tuning refers to the use of dynamic analysis to optimize the equipment selection and design of the entire conveyor system For example, dynamic analysis may show that adding a flywheel to a particular conveyor could significantly improve the starting or stopping behavior of the conveyor. An our drive suppliers specify

An electric motor's rotor, like any rotating mass, cannot become out of balance, unless something is either added to it, or taken away from it

But the components attached to the rotor can become unbalanced, such as

![[Solved] Two transmission belts pass over sheaves | SolutionInn](https://s3.amazonaws.com/si.question.images/images/E-M-E-V-M-S(238).PNG)