An Fitting Chart: The 2026 Standard For High-pressure Hydrogen Systems High Pressure Pumping

Global standards for bullets and spheres adhering to strict hydrogen storage spacing requirements is the most critical factor in the safe design of 2026 green energy infrastructure In addition to our standard products, we offer a complete line of valves and fittings for oil and gas industry use with sour gas (h2s). The compressed gas association (cga) has been producing standards for hydrogen systems for nearly 70 years

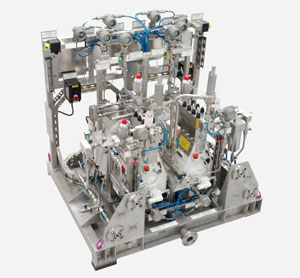

High Pressure Hydrogen Pumping Systems

Our growing library of 30+ safety publications and standards address the safe operation for producing hydrogen, storing hydrogen, delivering hydrogen, and applying hydrogen as a fuel source. In addition to our high pressure valves, we offer a complete line of reactors and pressure vessels and an expanded family of pumping systems and instrument valves Mapping safe hydrogen standards hydrogen safety standards are guidelines and regulations that are designed to ensure the safe storage, handling, and transportation of hydrogen

This map will help you identify the operational standards published by cga that best suit your needs.

Safety, codes, and standards nlr's hydrogen safety, codes, and standards projects focus on ensuring safe operation, handling, and use of hydrogen and hydrogen systems through safety sensors and codes and standards for buildings and equipment. Acceptable material forms are forgings, bars, seamless pipe, and seamless tubes which conform to the fittings chemical requirements, melting practices, and mechanical property requirements of. B31.12 sets piping and pipeline hydrogen service requirements typically used in petroleum, chemical gases, power generation, and clean energy industries. The new chapter will be required when the owner specifies its use

The organization of the chapter will be similar to the other chapters covering category m piping, high pressure piping, nonmetallic piping and high purity piping The plan is to have the changes incorporated into the 2026 edition of asme b31.3. Applies to facilities where hydrogen is produced, stored, distributed, or utilized Asme b31.12 also covers a broad range of system components such as pipes, fittings, valves, pressure vessels, and associated equipment.

Hydraulic fittings size chart includes npt, jic, bsp, orfs, orb etc

Please check out this blog for more details about the fittings charts. The standard addresses both low and high pressure hydrogen piping systems onsite from the point where hydrogen enters the distribution piping (the battery limits of the hydrogen storage system) to the point of use. High pressure valves, fittings and tubing 30,000, 40,000 and 60,000 psi service Explore dwyeromega's comprehensive range of industrial sensing, monitoring, and control solutions—from thermocouples to pressure transducers—engineered for precision and reliability.

Two clamp halves, held by four bolts, hold the connection together These are available in two pressure groups Standard (code 61) and high pressure (code 62). Compatibility is another incentive, as jic fittings are likely to mate with more standard hoses and adapters.

The fitting featured a 37 degree mating angle which provided superior sealing compared to the common 45 degree fittings and used a higher class of thread quality.

The standard applies to hydrogen piping in a supply system (to the source valve) and to customer piping from the source valve to the point of use For the purposes of this standard, high pressure is defined as gaseous hydrogen at service pressures equal to or greater than 3000 psi (20 680 kpa) High pressure equipment company has developed a line of medium pressure products to assure safe and easy plumbing through 20,000 psi Swagelok has hydrogen fuel cell solutions for the hydrogen energy market by using our safe, reliable fluid system components for containment and transfer needs.