The Torque Transmission Math Inherent To Every Qd Bushing China Sd Wly Co Ltd

Do not use extensions on wrench handles The split in the bushing wall can be gently increased to help slide the bushing along the drive shaft. There should be a gap between the face of the sheave or sprocket hub and the flange of the qd bushing to insure a satisfactory cone grip and press fit.

QD Bushing Sheaves | Yodify.com

Dimensions, ratings, and torque limits for different bushing sizes from qt to s That's where gates bushings come in, bringing speed, efficiency, and reliability to your industrial, commercial or automotive belt drive applications Gates qd™ (quick disconnect) bushings are engineered with precision tolerance for use with sheaves, sprockets, pulleys, and other power transmission applications.

Dimensions bushings are designed to transmit the rated torque capacity listed in the table below when the cap screws are tightened as the bushings are stocked in all popular bore sizes, including metric bores, within the bore range for a particular bushing.

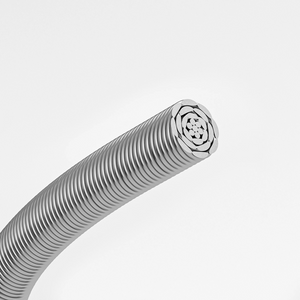

Home library power transmission bushings qd bushings qd bushings b&b manufacturing ® is a leading supplier of quick disconnect (qd ®) bushings for use in Timing pulleys sprockets sheaves gears our stock steel qd ® bushings feature torque capacity from 1,500 to 20,000 pounds and bore sizes from ½ to 7. A quick disconnect (qd) bushing is a specialized mechanical component used to rigidly secure power transmission elements like pulleys, sheaves, or sprockets onto a rotating shaft The distinguishing feature of the qd design is its tapered, split.

For heavier products, it is usually easier to either first slide the bushing onto the shaft, then slide the product onto the bushing (illustration 2a), or first position the. Ed holes indicated by alternately torque set or cap screws* to recommended torque setting in chart below On 3535 and larger bushings use a block, sleeve or drift and hammer large end of bushing (do not hammer bushing directly) Ammering, is the same as before hammer all unoccupied holes with gr

The qd design is the most popular and widely used bushing in the industry

The tight fit between the bushing and the shaft ensures a reliable and efficient transfer of power, minimizing slippage and maximizing performance. Qd bushings are easier to install and remove than tl bushings, as they do not require a keyway or set screws Qd bushings are generally more expensive than tl bushings How to choose or customize the right qd bushing?

What is a qd bushing A qd bushing, also known as a quick disconnect bushing, is a type of flanged bushing commonly used in hvac systems It provides a secure and efficient method for connecting rotating shafts to driven components. Qd bushings available in all letter codes

Double split taper bushings, interchangeable with industry standards

(all of our bushings are stocked in inch and metric sizes.) all bushings are manufactured to mpta standards. A qd bushing, also known as a quick disconnect bushing, is a mechanical device used to connect rotating shafts to hubs or sprockets It provides a secure and efficient way to transmit torque in various industrial applications. Conical bushings are used in various applications throughout the baggage conveyor industry

Typical uses are connecting power transmission components to drive Mst® bushings instructions the mst® bushings are easy to install and remove They are split through the barrel and have a taper to provide a true clamp on the shaft They are keyed to both the shaft and the hub to help during blind installations.

Quick disconnect bushings and sprockets available online through motion, filtered by brand, material, shaft size, and more.

A qd bushing, or quick disconnect bushing, is a type of bushing that is designed to provide a tight grip on a shaft It is used to mount pulleys, sprockets, and other components to a shaft quickly and easily.