The Thread Engagement Calculations For A Perfect 12-24 Tap Drill Size Npt Tp Chrt Koolindo

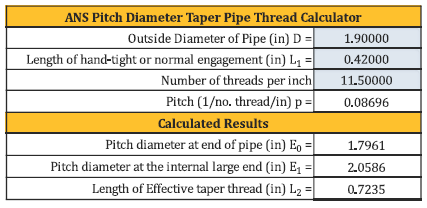

The size of the tap drill hole for any desired percentage of full thread depth can be calculated by the formulas below. The distance between vs after following a helical path around the diameter of the screw. Tap drill sizes the general rule of thumb for tap drill sizes (with 75% thread engagement) is to take the diameter (e.g

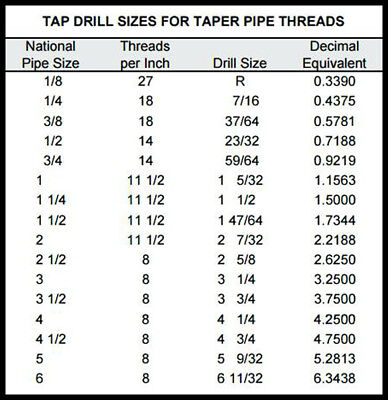

NPT Thread Tap Drill Size Chart NPT Thread Taper Angle, 44% OFF

10 mm) and subtract the pitch (e.g The distance between 2 adjacent v shapes 1.5 mm), giving the tap drill size (e.g

However, in some cases it is useful to either reduce the thread engagement (for example when tapping in hard materials) or increase it (for example when tapping thin materials)

Just choose your thread type (inch or metric), select the tap size or pitch, and set your desired thread engagement The tool instantly provides the recommended drill size along with guidance to help you get the best results. A tap drill calculator is a tool that helps users find the proper drill bit size needed before tapping a threaded hole This ensures optimal thread engagement and tool performance.

Tap drill size size formula's are theoretical based on the thread type and desired percentage of thread Please allow for the fact that drills generally drill oversize. The drill and tap size calculation determines the appropriate drill bit size needed before tapping threads The formula accounts for the major diameter of the thread, the percentage of thread engagement desired, and the threads per inch (tpi).

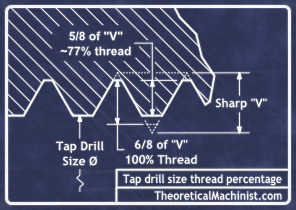

Past changes in the thread form designation of the basic thread height from 0.750h to 0.625h confused the calculation of percent of thread engagement

This calculation has been used in the past for threaded products users to determine tap drill size selection. Metric tap drill charts have the same drill size problem in that they use the same formula as that employed for the obsolete as threads In both iso and un thread series, having a range of useful drill sizes allows designers and machinists to tailor effective thread depth for long holes, various materials and thread strength requirements. Tap drill size calculator for inch and metric threads (for cutting and forming taps)

Plus formulas and charts for tap drill size. The tap drill size of a hole that will be cold form tapped is usually bigger than it cutting tap counterpart (77% thread is what you want to use) a 100% thread is 3/4 qtr, or (6/8 th), of the full 60° triangle which is the maximum allowed height of a full thread, the v shape, including flats. Basic thread dimensions (pitch, minor & major diameters, depth, lead), tolerance range for all applicable classes and much more

Understand thread engagement for selecting fasteners

Learn to calculate and choose appropriate engagement for strength. But with so many drill sizes and tap types available, choosing the right one can be overwhelming However, using the incorrect drill size can lead to costly mistakes, wasted time, and even safety hazards. By understanding the different types of threads, considering the material properties of the workpiece, and applying the right formulas and calculations, you can achieve the perfect fit every time

The benefits of calculating the correct tap drill size are numerous Improved accuracy, reduced errors, increased efficiency, and enhanced safety. Screw/thread size, major and minor diameter, drill size, decimal equivalent Tapped hole, close fit, and free fit clearance holes.

Unlock perfect woodworking threads with #13 drill size (0.182')

Calculations, tools, case studies & tips for heirloom joints that last. Discover the updated tap drill size chart with metric and imperial sizes Download the free printable pdf and master accurate hole sizing. Tap drill size calculator for ansi unified inch screw threads

Calculations are done for thread sizes from 0.060 to 2 inch. You can always use a scrap of material to test the drill bit to make sure you are on the right track. To avoid these problems, always (1) choose the correct drill size and tap for the material, (2) use a sharp drill bit and tap, (3) follow proper drilling and tapping techniques, (4) use a centering device to ensure accurate alignment, and (5) use a tapping die holder to secure the tap in place.

It also ensures proper thread engagement without having a loose thread

To use a drill bit tap chart, start by identifying the tap size and thread pitch you need for your project Determine whether the tap size is in the category of inch, metric, screw, or pipe (npt) sized Then look for the tap size in the chart in the dark gray column. Basic length of thread engagement that is defined by a combination of thread series, pitch and diameter

![Printable Tap Drill Size Chart Free [PDF]](https://www.typecalendar.com/wp-content/uploads/2023/01/Tap-Drill-Charts-300x225.jpg)