The Thermal Dissipation Strategy Inside Advanced Bearing Housings How To Select

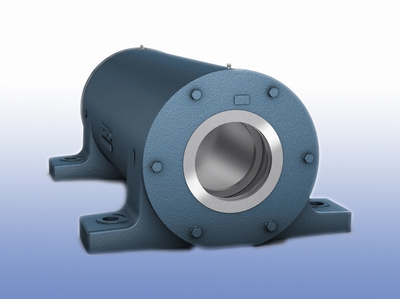

This balance between thermal management and mechanical durability highlights the importance of holistic design optimization, particularly in pressure differential management and geometric configuration, for advanced turbine bearing housing applications. The right material ensures that heat is evenly distributed across the bearing, minimizing localized overheating. Estimating heat dissipation from skf plummer (pillow) blocks for skf plummer (pillow) block housings, you can use a model based on bearing size to estimate heat dissipation values

Bearing Housings: Tips for Longevity - FHD

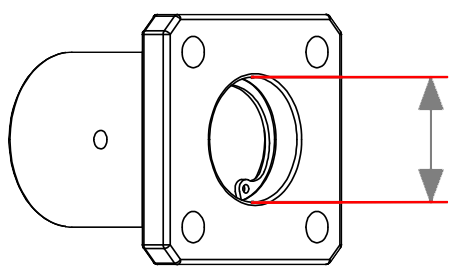

Using the diagram below, you can estimate the heat dissipation per degree above ambient temperature, w s, for a bearing with bearing mean diameter d m in a plummer block housing, with the shaft exposed to the. Materials with better thermal conductivity or heat resistance, such as ceramic or hybrid bearings, may help in reducing heat buildup This work aims to predict the temperature in the bearing from the thermal modeling of a rolling bearing

The model isbased on the law of conservation of energy in a transient regime, whose.

The purpose of this article is to develop a methodology and algorithm for calculating heat transfer in the bearing housing of a turbocharger in order to assess the effect of the thermal state of the tkr radial bearing on its performance and the rotor dynamics. For instance, certain polymers and composites are engineered to have excellent thermal resistance, making them suitable for use in demanding environments Additionally, the application of thermal coatings can further enhance the heat dissipation capabilities of cylindrical bearing housings. Heat removal from the bearing occurs by conduction, convection, and radiation through the bearing's system

The system's path of heat can incorporate the bearing housing, shaft, or other neighboring devices that transfer heat by conduction, convection, and radiation. The purpose of this reprintis to explore. Structural heat sinks embedded directly into bearing housings increase thermal mass and dissipation, providing robust cooling solutions The results demonstrate the exceptional thermal insulation capabilities of the heat dissipation runner structure, with a noticeable positive impact on thermal protection through appropriate flow rate increments

A simulation and analysis model for thermal insulation performance is developed and validated against experimental findings.

This typically results because of an imbalance between the frictional heat generation inside the bearing and heat dissipation to the surroundings Consequently, the bearing components undergo excessive thermal expansion resulting in sudden increase in the contact loads. Inside the gearbox the heat is transported by the oil, which is distributed by the rotating parts — like gears Without external cooling, the major part of the heat is dissipated by convection and radiation

Figure 1 influences on the thermal behavior of gearboxes (ref 1). As power densities increase, effective thermal management becomes critical to maintain device performance and prevent overheating Overheating can lead to device failure, reduced lifespan, and compromised performance [3] and wemekamp and luo [4], a more advanced calculation method is introduced

This method will be used in the current paper for the analysis of the gearbox thermal and efficiency behavior

Therefore, advanced thermal management technologies has become very necessary and essential. Thermal management is critical for optimising performance, extending lifespan, and ensuring the efficiency of bldc motors in various industrial applications It involves both design and operational strategies to minimise heat generation and enhance heat dissipation. To calculate the bearing temperature, divide the friction power loss by the heat dissipation per degree, then subtract the ambient temperature

How to calculate bearing temperature? Keeping thrust bearings cool is a matter of design with a different cooling strategy for each type of thrust bearing. Thermal deformation caused by internal heat accumulation is one of the main factors affecting machining accuracy Therefore, there is important theoretical and practical significance to accurately simulate and analyze thermal characteristics inside the spindle.

Bearing shaft and housing calculations are impacted by thermal expansion and centrifugal force

Learn more and contact gmn bearing usa here. Explore recent advancements in thermal management technologies used in wind turbines, ensuring optimal performance, efficiency, and longevity. The construction of a bldc motor consists of stator, rotor, bearings, housing, and other auxiliary components Each component requires careful material selection to ensure maximum efficiency, minimal energy loss, and long service life.

Choosing the right bearing material can improve the thermal management of gearbox bearings