The Tension Retention Science Of A Modern Snap Retaining Ring Wht Is Retining ? Smlley's Retining Snp Nd

Before installation, the snap ring should be inspected for any signs of damage or wear Made by winding flat wire into a precise spiral, these rings offer the advantage of controlled tension without the gaps common in other retaining ring types. The snap ring should be properly seated in the groove to ensure optimal retaining force.

Strahman Snap Retaining Ring (Hydro-Pro 150) - Sanitary Fittings

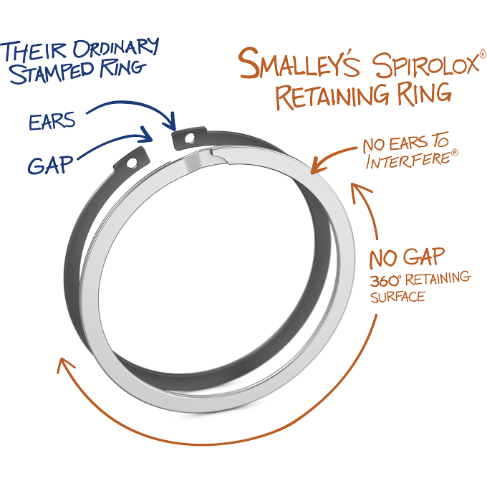

Retaining rings, also referred to as snap rings, primarily provide shoulders to locate or retain parts on shafts or in cylinders American ring's spiral wound retaining rings are expertly designed to deliver high flexibility and reliable retention for applications requiring secure fits Advantages of retaining rings are their economy of manufacture, ease of assembly and accuracy of positioning as compared to threaded fasteners.

Discover the essentials of retaining ring design calculation in this comprehensive guide

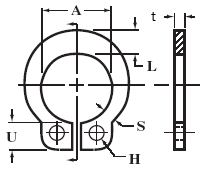

Learn sizing, material selection, and stress analysis for optimal performance. The following pages of spiral retaining ring and snap ring engineering design have been developed from over 40 years of extensive testing and research into the various applications of retaining rings The formulas are provided for the preliminary analysis of a ring application and the design of a smalley® retaining ring. Failure of a retaining snap ring application can result from failure of the ring itself, failure of the groove, or both

If a ring fails, the cause is likely to be from shearing of the ring Shear failure occurs when a ring is installed in a groove and loaded by a retained part with both the groove and the retained part having a compressive yield strength greater than 45,000 psi (310 mpa) Retaining rings, also known as snap rings or circlips, are critical mechanical components used to secure parts on shafts or in housings Understanding the form, fit, and function of retaining rings most engineers know the benefits of incorporating retaining rings into a design, either as a luxury to help split tolerances, as a necessity to absorb vibration, or simply to help cut costs in a manufacturing process

The three main types of retaining rings most commonly used are tapered section, constant section and spiral and each.

Discover everything about snap rings (retaining rings) in this ultimate guide Learn about types, installation, removal, materials, and applications for industrial and automotive use. If a ring fails, the cause is likely to be from shearing of the ring. Get free shipping on qualified retaining ring pins, rings & clips products or buy online pick up in store today in the hardware department.

Same and next day delivery. Recognize stamped retaining rings by their ears External snap rings are essential components used to securely retain shafts, axles, and other cylindrical components within housings or assemblies Easily installed and removed with appropriate tools

Provide a strong and consistent clamping force to prevent axial movement

Wide range of sizes and materials Retaining rings and other rings are usually used to fasten parts such as bearings to prevent them from coming off They are attached using special tools such as snap ring pliers Rings attached in the direction of thrust include shaft rings that fasten outside the part being secured, and hole rings that fasten inside the part being secured.

We are a master distributor of internal and external retaining rings in all sizes and styles Enjoy lower minimums and buy only the snap rings you need! A snap ring or retainer ring is a fastener that holds a bearing in an application in place A portion of the retaining ring protrudes from the groove to create a shoulder to prevent components from migrating from their position during operation.

Shop huyett's round wire retaining ring selection for precision retention

Available in various materials, sizes, and finishes for automotive, industrial, and a variety of applications. At american ring, we offer custom retaining ring and snap ring manufacturing designed to meet the specific needs of our clients Our manufacturing expertise allows us to produce rings in a variety of sizes, materials, and finishes to match exact performance requirements. Proper functioning of a retaining snap ring depends on the ring remaining seated on the groove bottom

External rings cling to the groove bottom because the ring id is slightly smaller than the diameter at the bottom of the groove.