The Tensile Strength Deep Dive For Next-gen Industrial Roll Chain Splitting Download Scientific Diagram

We take a deep dive into the two most common industry terms related to roller chain strength It also shows the common applications of each size. Tensile strength and working load

Tensile Strength: Definition, Importance, Types, and Examples | Xometry

We also compiled a list of the strongest roller chain sizes based on their corresponding ansi part numbers. This page shows the different sizes of ball chain and bead chain that we manufacturer Discover the diffirence between roller chain tensile strength and roller chain working load when you explore the durochain knoladge base

See our visual roller chain strength info!

Tsubaki ansi chains last longer and perform more efficiently, adding to your bottom line Weight ratings with these chains begin only over 1,000 pounds of tensile strength to over 150,000, providing plenty of power for nearly any application Anytime heavy loads or handle need to be lifted repetitively, roller chains provide an option with a long productive life and little maintenance. Learn about the essential performance features of roller chains, including tensile strength, fatigue strength, and wear resistance

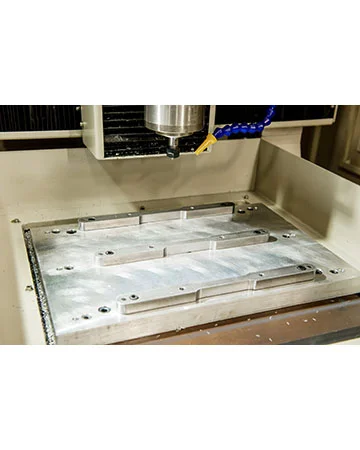

In this comprehensive article, we explore the significance of chain tensile strength, its calculation methods, and how it influences various industrial applications. These industrial roller chains meet ansi b29.1 standards but include thicker side plates than standard roller chains The thicker plates increase the roller chain's strength and fatigue resistance and reduce stretching and wear. Their inner and outer plates match the thickness of the next larger standard roller chain size, resulting in a tensile strength that is approximately 20% greater and a maximum allowable load that exceeds that of the d.i.d ansi standard roller chain by approximately 15%.

In summary, the valuable insights provided by this review pave the way for continued advancements in deep rolling techniques, ultimately contributing to the development of more durable,.

0.5 in inside plate height (in) 9.9 in number of strands/width 0.175 in pin length (in) 1.417 in plate thickness (in)

Extreme performance british standard roller diameter (in) 0.335 in base catalog no Steel minimum tensile strength (lbs) Learn about the different types of roller chains and the advantages each brings while providing reliable and efficient power transmission.

The tensile strength of the base material—i.e., the ultimate breaking strength—determines the rating and grade given to the particular chain

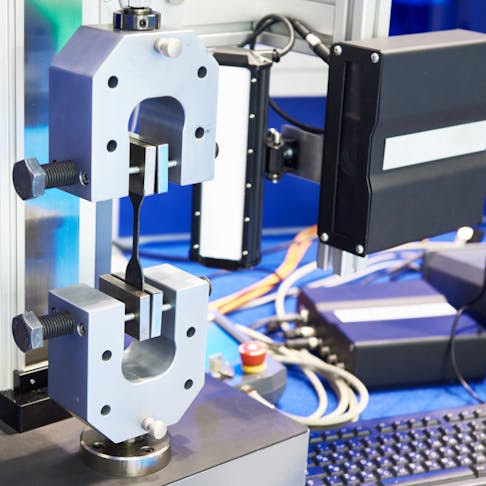

The greater the breaking strength, the higher the grade, and vice versa The grade indicated for a chain helps industry professionals identify the types of applications for which it is appropriate. Plate height plate thickness pin diameter overall width average tensile strength average weight per foot each of these measures helps you determine which grade 100 chain is right for your unique application Chain tensile strength test project brief project objectives

Independently tensile test chains to determine Coil (opening size) finish (corrosion resistance) chain grade grade refers to the tensile strength of the metal The grade number used by manufacturers indicates the ultimate break strength of chain The higher the grade, the greater the break strength

With galvanized chain, it basically boils down to how much carbon is in the steel.

Dimension shown is bushing diameter roller type s indicates a standard roller. Choose for quality roller chain solutions. 8500 sold in 50ft box. Our #10 (4.8 mm) ball chain spools are made in the usa

Commonly used in plumbing, window blind and retaining applications. Heavy duty roller chain is able to withstand more demanding industrial & agricultural applications for longer periods of time over standard ansi roller chains 80h roller chain can be used on the sprockets as 80 roller chain, so you can easily upgrade to our 80h chain We also offer extra 80h connecting links & 80h offset links.