The Structural Engineering Strategy Behind Every Shaft Clamp Home

3.1 principles of clamping the basic functions of clamps are fourfold Engineering drawings are the industry's means of communicating detailed and accurate information on how to fabricate, assemble, troubleshoot, repair, and operate a piece of equipment or a system. (a) the workpiece must be held firmly even when the tools/cutters are in operation

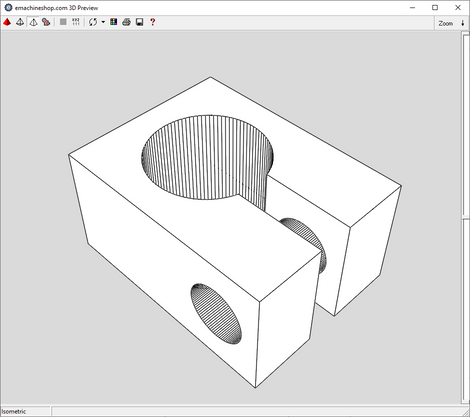

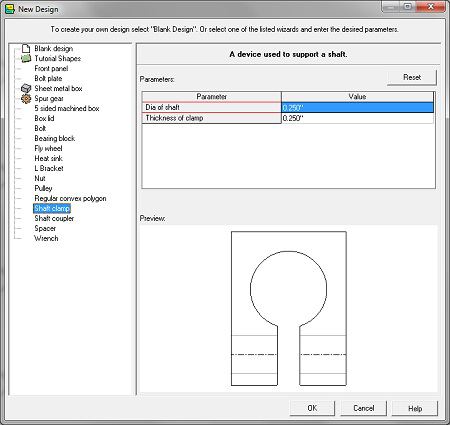

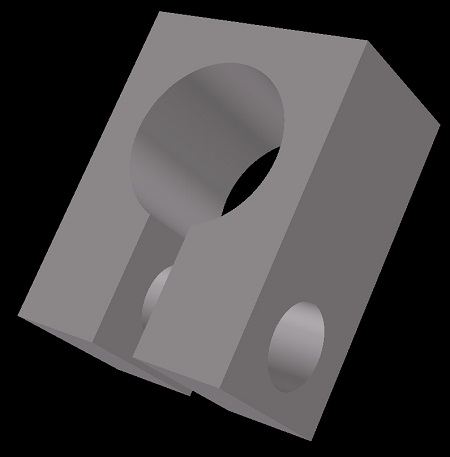

Free Shaft Clamp Design Software | eMachineShop

(b) the clamping device should be quick acting as the loading and unloading time should be as quick as possible They will be used extensively in statics, and you will use them again in other engineering courses so your effort to master them now is worthwhile. (c) when subjected to excessive vibration or chatter, the clamps should be firm and should not loosen up.

Frequently asked questions about the engineer's ultimate guide to mastering clamp designs now what core topics does the engineer's ultimate guide cover

This comprehensive guide delves into fundamental principles and advanced techniques for creating effective and reliable clamp solutions It covers material selection, force analysis, manufacturing considerations, and best practices essential. This document discusses the principles and design considerations for clamps It covers topics such as positioning clamps to direct force onto supported parts of the workpiece, using sufficient clamping strength, and designing clamps for quick action, minimal operator fatigue, and to accommodate workpiece variation

Different types of clamps are also described, including screw clamps, hook bolt. These tests confirmed that the clamp consistently delivered the intended clamping force and maintained its structural integrity Force analysis and stress calculations for mechanical clamps in context of mechanical clamp design 08 sep 2024 tags Force analysis and stress calculations for mechanical clamps

A comprehensive approach to design optimization abstract

Mechanical clamps are widely used in various industries, including manufacturing, construction, and aerospace, to secure and. Clamp a clamp is a device used to secure a work part in its manufacturing position by applying external forces There are various types of clamps, including strap clamps, screw clamps, swing clamps, c clamps, cam clamps, and toggle clamps A structural engineering group uses the results from the stress analysis to design the supports and connections to structure

However, do not generally implement the design into the project model to ensure that the supports are clash free and constructable in the field. Explore the fundamentals of bolt strength analysis including tensile strength, shear strength and proof loads for reliable structural connections. This compressive force that the structural elements experience is called the clamping force or clamping load In a way, it is a measure of the tightness of the bolted joint.

However, behind the smooth operation of these transport systems lies a crucial architectural feature

The structural failure of a traction motor mounting bracket occurred in service Fortunately the motor was prevented from falling onto the tracks by a cardan shaft protection ring thus preventing a catastrophe but the issue was taken very seriously by our client and was quickly elevated to the executive level. Many important considerations in bolted joint development are often overlooked While estimating the bolt tension achieved for a given tightening strategy is certainly a common focus, the effect of load on joint components is less fully discussed and understood.

If the applied load (f) is allowed to increase, the clamp force acting on the joint will continue to decrease until the joint is fully unloaded, as can be seen in bolted joint diagram 3 (∆j = 0) Any further increase in the applied force will result in a gap between the plates and the bolt sustaining all of the additional force. The clamp load calculator is a vital tool used in mechanical engineering and manufacturing to calculate the amount of force applied to a fastener when a torque is applied. Free body diagrams are the tool that engineers use to identify the forces and moments that influence an object