The Logic Control Architecture Inside A High-performance Dc Drive Hierrchicl Of Microgrid Downlod

The approach dynamically adjusts control parameters under varying conditions. The fuzzy control laws are developed to regulate the motor speed and maintain the current at a limiting value For servo drive applications, dc motors are still used, although they are also being replaced by bldc motors

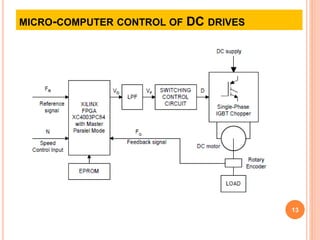

Micro computer control of dc drive | PPTX

In this lesson we discuss speed and position control with dc motors Two fuzzy controllers are proposed for the drive system, namely, speed and current controllers The next lesson discusses adjustable speed drives using induction motors, while lesson 35 discusses bldc servo drives.

Combining digital control technologies with both brushed and brushless dc motor drives improves their performance

In the drive system, microcontrollers or digital signal processors (dsps) make it possible for complicated control algorithms to work. A dynamic braking contactor is also included in drives up to and including 350 a models The task for the control engineer is to ensure that the output of the dc motor follows a predefined reference both under normal operating conditions and in the presence of disturbances. Abstract fuzzy control of the speed of electric drives is an alternative in the field of the control system

Modeling and simulation of electric drive control systems based on fuzzy logic is an important step in design and development This chapter provides a complete means of modeling and simulation of fuzzy control systems for dc motors, induction motors, and permanent magnet synchronous. The cpu controls all system activity primarily through its processor and memory system The cpu consists of a microprocessor, memory chip and other integrated circuits to control logic, monitoring and communications

The cpu has different operating modes

In programming mode the cpu will accept changes to the downloaded logic from a pc When the cpu is placed in run mode it will execute the. Dc drives can control the performance of dc motors by adjusting the voltage and current supplied to it, in turn managing its speed, torque, and direction They first convert alternating current (ac) power to dc, then regulate that output to facilitate both stable and programmable motor behavior.

The picture shows the general layout of a dc drive configuration In this example, the power supply is a medium voltage line which connects the dc drive via a power transformer to the supply network From this point there is a difference between the armature and the field circuit which will be discussed separately. A plc, or programmable logic controller, is a computer built to function reliably under the tough conditions of industrial environments like extreme temperatures or dusty areas.

However, choosing the right product can be difficult because many manufacturers lack diverse package options, product features and support.

Fuzzy logic (fl), which was first introduced by zadeh on 1965 [4] as one class of artificial intelligence (ai), has been shown to be successfully applied to the motor drives in the industrial applications, transportation systems, aerospace, house appliances, etc Fuzzy logic controller (flc) for the speed control loop has been shown to have. Drive systems for dc motors improved drive systems have made both brushed and brushless dc motors much more useful and expanded their abilities This part goes into detail about the design and operation of drive systems made for these two types of dc motors

It shows how electronic control has changed their dependability, efficiency, and range of uses Design and operation of drive systems for. In the literature, the control of electric drives based on fuzzy logic is studied in many works Several matlab programs for modeling and simulating electric drive systems based on fuzzy logic are presented on the matlab website as well

Introduction the advent of motor drives has profoundly influenced diverse domains, encompassing industrial, medical, and aerospace applications [1]

We help our customers, partners and equipment manufacturers to improve energy efficiency, asset reliability, productivity, safety and performance. Introduction dc motor provides easy controllability and high performance, due to its speed can be varied within wide boundaries Dc drive has vast applications such as electric traction, electric cranes and robotic where manipulation of speed controller is required to perform their tasks [4] In general, the control of systems is difficult and mathematically tedious due to their high.

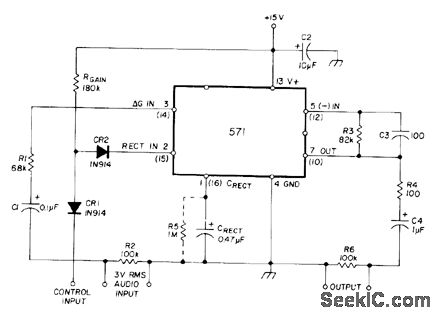

Motor drivers match the requirements of different motor types like brushed dc, stepper, bldc, etc 1.2 ssd's architecture a basic block diagram of a solid state drive is shown in fig.1.1 In addition to memories and a flash controller, there are usually other components Of course, reasonable filter capacitors are inserted for.

A programmable logic controller (plc) controls the manufacturing processes for integrated production lines and equipment

Plcs were designed to replace the need for a large bank of relays or timers in…