The Friction Reduction Research Powering The Modern Regal Bearing Optimizing Through News

Abstract friction reduction is necessary in order to decrease engine emissions, so bearing friction needs to be reduced but with the constraint that low friction solutions should not affect bearing reliability Organic friction modifiers are added to engine oil formulations to reduce friction between two surfaces and can have dramatic effects on this loss of energy, with friction reductions of up to a factor 5, but little is known about how these modifiers actually work… To meet this target of low friction and high reliability bearings, several technical solutions are reviewed.

Optimizing friction through modern bearings - BEARING NEWS

This work investigates the mechanisms for friction reduction in textured journal bearings A significant proportion of fuel energy in transport is lost to friction Experiments covered several working conditions, and the friction and lubricant film temperatures were measured for three texture configurations

These include but are not limited to light weight designs, load distribution improvements, thermal management, and friction reduction

This paper focuses on frictional torque reduction only. Highlights calculation methods of friction torques and power losses of rolling element bearings are discussed The development directions of bearing friction torque are given. As research and development persist, these breakthroughs will undoubtedly continue to shape the landscape of modern engineering and industry

By embracing these innovative bearing designs, industries are paving the way toward a future where machinery operates with unprecedented precision, reliability, and sustainability. The future of bearings is being shaped by groundbreaking innovations in material science and design Friction reduction research and development southwest research institute® (swri®) has a long history of providing comprehensive friction reduction solutions to help meet increasingly stringent emissions regulations for engines and powertrains Swri works closely with engine manufacturers, tier 1 suppliers, and fuels and lubricant companies to isolate, quantify, and reduce friction sources.

To meet this target of low friction and high reliability bearings, several technical solutions are reviewed

Particular attention is paid to evaluating friction reduction performance for each. The functionality of automotive bearings in vehicles consists of three important aspects which involve implementing smooth motion along with friction reduction to deliver better fuel efficiency Modern technological progress and sustainability needs create favorable conditions for extraordinary transformations to occur in automotive bearing development by 2025 A ball bearing a bearing is a machine element that constrains relative motion to only the desired motion and reduces friction between moving parts

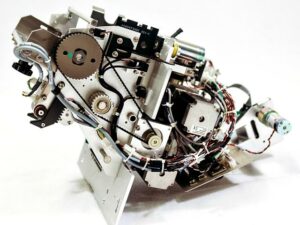

The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis Or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts Rolling bearings are mechanical elements that guide the rotation while supporting the load by rolling motion of rolling elements They are used for supporting the rotating shaft of various industrial machines and contribute to reduction of energy consumption and heat generation by reducing friction, suppression of wear and prevention of seizure.

How do ball and roller bearings work

Ball and roller bearings reduce friction by allowing smooth rotation between the bearing surfaces The rolling elements (balls or rollers) minimize friction compared to sliding motion, improving efficiency and prolonging the life of the bearing What are the benefits of using active magnetic bearings? Explore how ball bearings reduce friction between moving parts in machinery

Understand bearing function and optimize performance. On other hand it results in massive friction losses which causes energy loss and heat generation An accurate estimation of friction torque measurements becomes essential to estimate bearing power loss accurately. Roller camshafts significantly reduce friction, leading to enhanced engine power and efficiency in vehicles

At carworship, we explore how this technology benefits automotive enthusiasts and engineers alike

Understanding roller camshaft performance is crucial for selecting the right. The meaning of roughness less roughness of rubbing surfaces of bearings and gear teeth results in less friction Less friction means less wear, and less wear prevents failures and system insecurity This would certainly lead to positive effects as cost reduction, material and energy savings, less co2 emissions as well as greater sustainability.

Mcgill is the first choice for industries needing custom bearings that work well even under extreme conditions, because they can tweak their designs to suit each specific task Contributions to modern bearing technology reliability and innovation in bearing design mcgill has made big strides in bearing technology. Explore the essential role of bearings in mechanical engineering, including their types, importance in reducing friction, and proper maintenance techniques This comprehensive guide covers popular brands like timken, ina, and fag bearings, detailing how correct bearing selection can enhance machinery efficiency and longevity

Learn about the impact of load distribution, operational speeds, and.

Bearings are crucial in minimizing the surface contact between moving parts, significantly lowering friction This reduction is vital as it helps to decrease wear and tear, reduce energy consumption, and prolong the lifespan of machinery. The result is improved product quality, optimized performance, and minimized downtime Driving sustainability in manufacturing modern manufacturing is about more than output

Skf bearings are designed to contribute to energy savings and longer service life, reducing both environmental impact and operating costs.