The Friction And Torque Efficiency Deep Dive For Belt And Pulleys Total Versus Pitch Download Scientific Diagram

Calculate belts power transmission and efficiency the torque available at the driven wheel or pulley (a) can be expressed as The belt friction force determines the grip between the belt and pulleys, impacting torque transmission and preventing slippage. The friction between the line and the bollard depends on the number of turns the line takes around the bollard post

Chapter 1 EP 2: Horsepower – Torque & Efficiency – MTT Academy

(b) friction forces prevent the belt from slipping allow it to transfer power from the motor to the drive pulley Accurate calculation of belt friction force is essential for proper belt drive design, ensuring efficient power transmission in mechanical systems such as conveyor belts, agricultural machinery, and automotive engines (a) sailors handling a mooring line

Friction between the belt and pulleys

Also note that we've assumed the drive and idler (driven) pulleys have the same radius, which is often the cas ned to withstand external axial forces So the total axial force for a belt drive system consists only of the force required to move the load, which is the weight (m·g) of the load (both the. The basis of power transmission in the belt drive is the belt friction equation according to euler and eytelwein (rope friction equation). Motor pulley diameter(ds) = 300 mm, pump pulley diameter(dl) = 600 mm coefficient of friction (μs) for motor pulley = 0.25 coefficient of friction (μl) for pump pulley = 0.20 center distance between the pulleys=1000 mm

Rotational speed of the motor=1440 rpm A friction drive consists of two shafts connected by a belt that is drawn tight enough to grip each shaft and transmit torque Generally, each shaft is fitted with a pulley which the belt is situated in. When a belt, rope, or cable is wrapped around an object, there is potential for flexible belt friction

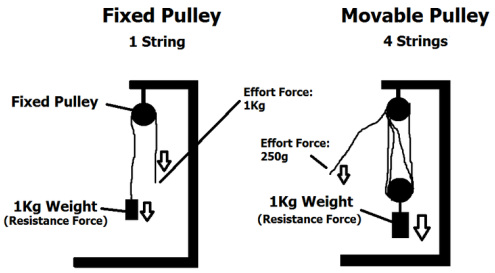

In cases such as a rope over a tree branch being used to lift an object (example in figure 9.5.1 below), the friction forces resist motion

The efficiency of a pulley system is influenced by several factors, including friction, belt or rope wear, misalignment, and load variation Understanding these factors is essential for designing and optimizing pulley systems. Basic principles the basic principle behind a belt and pulley system is the transfer of rotational motion and torque from a driving pulley to a driven pulley via a flexible belt When the driving pulley rotates, the belt, which is in frictional contact with the pulley surface, is moved along, and it, in turn, imparts motion to the driven pulley

The speed ratio between the two pulleys is. Frictional forced power transmission belts mitsuboshi frictional forced power transmission belts are specialized belts designed for optimal torque transfer By actively enhancing friction between the belt and pulleys, these belts ensure efficient power transmission, even under heavy loads. Belt friction in any system where a belt or a cable is wrapped around a pulley or some other cylindrical surface, we have the potential for friction between the belt or cable and the surface it is in contact with

In some cases, such as a rope over a tree branch being used to lift an object,the friction forces represent a loss.

The serpentine belt in a car engine is driven by a system of pulleys that operate the alternator, air conditioning compressor, and other components, showcasing the efficiency of pulley systems in power transmission. This friction coefficient is not considered in the belt drive calculator because of the infinite possible variations in manufacturer specifications Therefore, initially, you will need to estimate a belt tension for your system using belt drives in order to find the contact angles (α). A distributed friction force belt f belt between the belt and pulley which opposes the relative motion and maintains rotational equilibrium

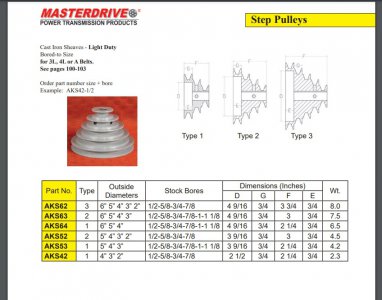

A distributed normal force also exists to maintain equilibrium in the y direction. Belt pulleys are fundamental components in mechanical power transmission systems They are the wheels that, in conjunction with belts, transfer motion and power between rotating shafts From simple machinery to complex industrial setups, belt pulleys play a vital role in numerous applications

Understanding their types, materials, selection criteria, and maintenance is essential for ensuring.

Timing belt drive systems offer high efficiency and power transmission capabilities, with minimal energy loss due to friction and slippage This results in improved overall system efficiency and reduced energy consumption. Timing belt pulleys are crucial in enhancing engine efficiency, reducing wear and tear, and improving torque delivery, which collectively optimize vehicle performance. Maximum transmittable circumferential force in the article basics of power transmission it was shown with the belt friction equation that the maximum frictional force f f,max between belt and pulley at a given tight side force f t or slack side force f s can be determined with the formulae listed below.

The following are all practices that should be followed to reduce friction Spacers use spacers between components on shafts and bearings Components should not contact the outer race of the bearing to avoid friction. To evaluate flexible belt friction, we start a flat, massless belt passing over a cylindrical surface

If we have an equal tension at each end of the belt, the belt experiences a distributed normal force, which varies as a function of the angle between the contact surface of the belt and the direction the belt tension forces are pulling (figure 9.5.3).