The Frequency Inverter Science Behind A Modern Adjustable Rpm Motor S Mnufcturers

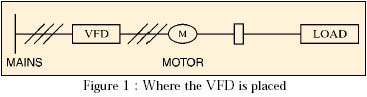

Introduction to frequency inverters (vfds) frequency inverters, also known as variable frequency drives (vfds), are essential components in modern motor control systems As a result, the motor rotates in the direction of the resultant torque. In industries ranging from manufacturing to hvac systems,…

Frequency Inverter | inverter.com

The frequency inverter also enables the motor to ramp up and down smoothly Interaction between the magnetic fields of these electromagnets generates twist force, or torque The frequency inverter is therefore a controller for a drive with a variably adjustable frequency that regulates the machine (e.g

The motor speed) via parameters such as the frequency

In this way, motors and electrical machines can be controlled very precisely in. The use of an inverter to adjust the speed and acceleration of an ac motor increases the range of applications of the motor compared with a motor that operates at a constant speed The speed of a motor is normally measured as the number of revolutions per minute (rpm). The inverter is the core part of a frequency inverter, which converts a dc power supply into an ac power supply with variable frequency and variable amplitude to control the speed of a motor.

A frequency inverter is an electronic device used to control the speed of an ac motor by varying the motor's input frequency and voltage By doing so, it provides flexibility in managing motor speed and torque without the need for mechanical speed control systems. A frequency inverter is an electronic device that converts the fixed frequency and fixed voltage from your electrical supply (e.g.,50hz or 60hz,240v or 480v)into a variable frequency and variable voltage output.this allows the operator to precisely control the speed and power of a standard ac induction motor. Frequency inverters convert fixed line voltage or frequency into variable line voltage or frequency the main function of a frequency inverter is to convert the frequency of ac voltage coming from the mains system into a variable frequency so that the speed of the connected motor can be adjusted.

Frequency inverters optimize motor speed, enhancing energy efficiency, precision, and scalability in industrial automation while reducing costs and emissions.

When choosing ac motors, important factors include supply voltage, phase configuration, frequency, and whether variable speed motor control—such as with variable frequency drives (vfds)—is required for your equipment or process. 4.1 inverter for variable frequency and magnitude, voltage source inverters are devices which convert the constant dc voltage level to variable ac voltage As specified in the function, these inverters are commonly used in adjustable speed drives Figure 8 shows a voltage source inverter with a supply voltage v dc and with six switches.

However, the simplest of vvvf inverters can only vary voltage and frequency applied to the motor terminals The key differences lie in the details of the engineering design, the approach to control, which results is better performance characteristics. The faraday disk was the first electric generator When the disk was turned, this induced an electric current radially outward from the center toward the rim

The current flowed out through the sliding spring contact m, through the external circuit, and back into the center of the disk through the axle.

With a sinusoidally modulated (spwm) inverter, indicated in fig 33.17, the supply frequency to the motor can be easily adjusted for variable speed Equation (33.18) implies that, if rated airgap flux is to be maintained at its rated value at all speeds, the supply voltage v1 to the motor should be varied in proportion to the frequency f1. This method is effectively used to control the variable voltage and frequency generated by the variance of the waves.

A variable frequency drive (vfd) is a device that controls the speed and torque of an ac motor by adjusting the frequency and voltage of the power supply A vfd consists of three… A brushless dc electric motor (bldc), also known as an electronically commutated motor, is a synchronous motor using a direct current (dc) electric power supply. A tesla model s p85+ recovering regenerative braking power in excess of 60 kw

During regenerative braking the power indicator is green

Electric motors, when used in reverse, function as generators and will then convert mechanical energy into electrical energy Vehicles propelled by electric motors use them as generators when using regenerative braking, braking by transferring mechanical. Westinghouse would have selected a low frequency of 30 hz to drive motor loads, but the turbines for the project had already been specified at 250 rpm. 10 start the motor switch on di1 (forward) or di2 (reverse)

Use the potentiometer on ai1 to set the reference frequency, adjustable from lsp [low speed] to hsp [high speed]. The operation of the electricity network has grown more complex due to the increased adoption of renewable energy resources, such as wind and solar power Using energy storage technology can improve the stability and quality of the power grid One such technology is flywheel energy storage systems (fesss)

Compared with other energy storage systems, fesss offer numerous advantages, including a.

2.1 definition of electric motors an electric motor is a machine used to transfer electrical energy into mechanical energy An electric motor requires an interaction between the rotating parts and the stationary parts