The Fail-safe Mechanical Logic Of The Modern Jaw Couplings Alexandris

The coupling can still operate even if the spider breaks The table below shows some examples of isa binary logic symbols. The driving jaws simply rotate until they contact the driven jaws directly, and the coupling continues to function (albeit with considerable noise and accelerated wear).

Jaw Couplings | Hayes Manufacturing, Inc.

In contrast, an oldham coupling with a similar failure mode of it's' center disc will disengage and not allow continued power transmission. These symbols are used in logic diagrams, such as digital circuit diagrams or ladder logic diagrams, to depict the logical relationships and operations performed on binary signals Vibrations and shocks are effectively damped and absorbed

Jaw couplings are a robust and popular solution for transmitting torque between two shafts

This document discusses the most common failure modes of jaw couplings, which include normal wear, torque overload, misalignment, environmental factors, and vibration It provides examples of each failure type with photos and explanations As drive components in a wide variety. Jaw coupling computer drawing of a curved jaw coupling in mechanical engineering, a jaw coupling is a type of general purpose power transmission coupling that also can be used in motion control (servo) applications.

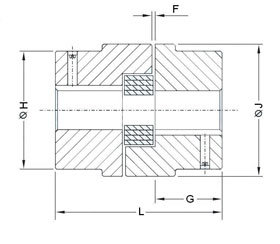

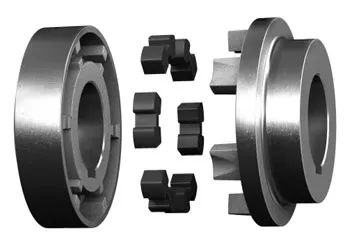

Jaw couplings are mechanical equipment used to connect two shafts in power transmission systems A jaw coupling is made up of a rubber spider insert, two hubs, and an additional part The flexible component of the jaw coupling is manufactured from rubber or polyurethane, providing certain minor separation between the shafts with flexibility and shock absorption The two hubs of jaw coupling.

Jaw coupling jaw coupling absorbing incidental misalignment, shock loads and small amplitude vibrations, fenner® jaw couplings offer a low cost flexible solution for most applications.

Best pulleys & couplings (p) ltd The torque is transmitted via elastomers between the cams that furthermore serve for compensating for displacements and damping shocks and torsional vibrations Fenner power transmissions' jaw couplings are the ultimate fail safe Designed to provide excellent flexibility, with the capacity to counter misalignment and absorb accidental shock loads, the.

Pros choose propress because there are more fitting configurations approved for more applications than any other brand. The torque is transmitted via elastomers between the cams also serving to offset displacements and dampen shocks and torsional vibrations The document provides instructions for selecting the appropriate jaw type coupling from lovejoy for connecting equipment like motors, pumps, compressors etc It outlines a 7 step process to determine the required nominal torque, application service factor, elastomer material, coupling size, bore size and item number based on application details like horsepower, rpm, shaft sizes, operating.

A jaw type coupling are fail safe as the tenons will interlock and continue power transmission

Depending on your application you may want a fuse type coupling, for example, if you have a process where a machine jamming is possible, perhaps a letter sorter. For mounting the hubs of the elastomer coupling are simply pushed on the shafts and axially fastened via setscrews. Its characteristic table shows how the output (qn+1) changes using inputs (j & k) along with the last state (qn). Binary logic symbols binary logic symbols are used to illustrate binary logic functions in a system