The Dynamic Balancing Science Required For 2026 Motor Pulleys Machines India

For speeds above this, or when the pulley diameter is less than 7 to 10 times the face width, dynamic balancing is recommended We balance fans, pulleys, electric motors, armatures, spindles, pumps, turbines, crankshafts, boring tools, cutting tools and anything else that rotates. They will operate safely at belt speeds up to 6,500 feet per minute, but at speeds over 5,000 feet per minute and at any speed where vibration is a problem, dynamic balancing is.

Dynamic Balancing Machines, Dynamic Balancing, India

The balancing system's ultimate readout of the required correction of 0.77 (weight units irrelevant) simply means the required correction is 0.77 washers The basic design philosophy of hard bearing dynamic balancing machines is measuring force and the advancement of computational mathematics using microprocessors has enabled introduction of balancing machines whose calibrations are valid for the complete range of speeds, weights and quality requirements. The included angle b between vectors o and t is measured from the diagram

This represents the location of the required correction relative to the location of the trial weight.

Explore the definition, applications, and precision grades of dynamic balancing, a critical process for reducing vibration in rotating machinery Learn its importance, methods, and standards. It is possible for a pulley to be statically balanced but dynamically unbalanced (although the reverse is not true), so dynamic balance must be measured as the pulley rotates Because it involves forces in two planes, dynamic balancing requires the addition of mass in two planes to neutralize imbalances and avoid vibrations in the pulleys.

In conclusion, the dynamic balancing of timing belt pulleys is a critical factor that should not be overlooked The consequences of an unbalanced pulley can range from minor annoyances, such as increased noise and vibration, to major system failures and costly repairs. Learn how to perform static and dynamic balancing on rotating machinery, from theory to worked examples, using hbk measuring equipment. Dynamic balancing our solution equipped with a schenck balancing bench, we can balance several parts of spindles and industrial motors at our workshop

We offer this solution for shafts, impellers, fans and pulleys

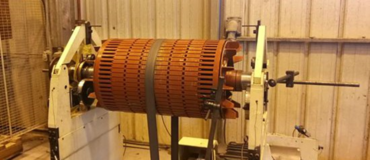

During the balancing process, our experts ensure that the parts meet the manufacturer's tolerances. Balancing machine is an industrial machine The machine is located in a factory environment along the process line Many types of industrial noises electrical, mechanical, magnetic will exist in an industrial environment

Besides this balancing machine has drive elements like motors, pulleys, belts which also rotate along with the component The component is mounted on rollers, and rollers. Our experienced engineers can design and manufacture the necessary parts, taking into account the required tolerance The dynamic balancing process will help save money and keep equipment in working order for years to come

We provide dynamic balancing services to various industrial sectors.

Pulley balance, or more importantly imbalance, is broken into dynamic and static Static, which is more common, is used to prevent the pulley from rotating due to the force of gravity When a pulley is out of balance, there are areas of the drum which are heavier than others These heavy spots tend to want to sit at the bottom of the pulley due to the pull of gravity

If you can't get it to your satisfaction, take all the rotating parts to a race car engine builder or a balancing place In 1962 i had all the reciprocating and rotating parts of an mg engine and clutch statically and dynamically balanced by edelbrock engineering in los angeles. Dynamic balancing services, in house balancing services, field balancing, rotor repair services, vibration analysis services, in situ balancing, laser shaft alignment. I balance the intermediate pulley shaft for the schaublin lathe

The same method can be used on any rotating item.camera

Importance of dynamic balancing in pulleys dynamic balancing is a critical aspect of pulley design and manufacturing It make sure that the pulley operates smoothly, reducing vibrations and enhancing the lifespan of the entire system. Why is dynamic balancing more complex than static balancing Dynamic balancing requires correcting imbalances in multiple planes along the length of the rotor, which involves more precise measurements and adjustments compared to static balancing.

Like the balancing of car and truck tires, but with much greater precision, dynamic balancing of sprockets ensures that vibrations caused by unbalance are minimized, reducing component fatigue. The motor is the often overlooked component, however bearings, pulley condition, electrical fluting (with vfd driven motors), often causes problems that could potentially cause more significant problems than an unbalanced rotor We perform this complete diagnosis of corrective maintenance to make sure you know the condition of the entire machine. Torque required for constant velocity

For a belt drive system, the motor torque required during constant velocity is simply the total axial force (fa) on the belt multiplied by the radius r

Introduction 1.1 causes of unbalance 1.2 types of unbalance 1.3 benefits of balancing 2 Balancing machines 2.1 introduction 2.2 soft.| find, read and cite all the research.