Scientists Debate The Precision Vs Cost Of Pcb Linear Actuators 4 Types

But along with its premium performance comes a higher price tag compared to the traditional ball screw linear actuator Actuators play a critical role across a multitude of industries, functioning as the driving force and check pneumatic actuator cost. Electromagnetic drive system the linear motor operates on a fundamental shift in motion mechanics

Micro Precision Linear Actuators

This is especially the case when it comes to equipment and machinery involving electric linear actuators There are going to be functional limitations to how quickly you can get that lead screw to turn with a small compact motor. Factors such as backlash, build tolerance, mounting alignment, and application dynamics can greatly affect the precision and accuracy of linear motion systems using electric linear actuators.

Understanding precision and accuracy in micro linear actuators precision and accuracy are often used interchangeably, but they refer to different aspects of motion control

Precision (sometimes called 'repeatability') refers to how consistently an actuator can reach the same position when given the same command Accuracy is how close the actuator's actual position is to the intended. Their precision affects positioning in robotics and medical devices, while efficiency reduces power consumption and system wear By considering factors like motor type, feedback systems, and load conditions, you can choose the best actuator for your needs.

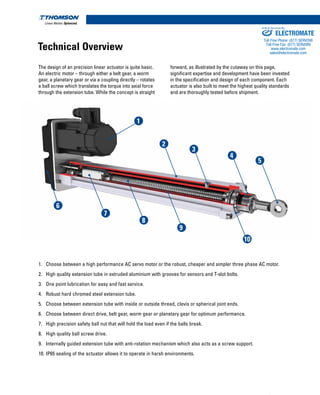

Linear actuators, responsible for translating rotary motion into linear movement, are at the heart of this precision Any deviation in their performance can lead to costly errors, product defects. One of the most common uses of motor linear actuators is in the field of robotics. Linear motor actuators and piezoelectric actuators are both known for delivering high precision, but linear motor actuators offer several technical advantages

In addition, the way each actuator is deployed has significant influence on the results

While there are numerous actuator styles/types available that are manufactured to various degrees of precision and subsequent cost, this example actuator may have high repeatability and deliver excellent performance even without it being highly accurate. Accuracy grades are a critical factor in the performance of linear motion components like bearings, actuators, ball screws, and linear rails These grades measure the precision of these components, relying on parameters such as lead error, straightness, and flatness, which directly impact a system's overall functionality and efficiency. Explore the world of actuators in this article that discusses their types, principles, and various applications across industries

From defining what an actuator is to examining various classification criteria, this article provides a clear understanding of these essential components in automation systems Discover the role of energy sources, power converters, controllers, and loads in the. Electric linear actuators precise control of position and speed are core strengths of electric linear actuators These actuators are programmable and designed to be flexible.

An important point about electric linear actuators, and one that sometimes causes confusion, is that the motion is provided by an electric motor, which rotates

Thus, an electric linear actuator converts rotary motion into linear As a side note, there are other forms of linear electric actuator that don't use a conventional electric motor. Choose electric if you require precision, programmability, and quiet operation with better energy efficiency. Hydraulic systems require regular maintenance to prevent leaks and ensure proper functioning, which can increase operational costs and downtime.

A linear actuator is a device that is used for creating linear motion, in contrast to the rotary motion created by a standard electric motor Linear actuators convert the rotary motion of an electric motor to linear motion, saving product designers the hassle of engineering a solution themselves. Learn how vcas can be selected for smooth, accurate, and responsive linear motion. Discover their applications, advantages, and customization options to find the perfect fit for your project.

As a manufacturer of both electric and pneumatic linear actuators, we'd like to bring some balance to the discussion

Electric linear motion has benefits as do pneumatic solutions. The precision of a micro linear actuator depends on multiple factors, including stroke length, gear ratio, and actuator type Electric cylinder actuators, or simply electric cylinders, are increasingly becoming a favorite for many industrial applications, overshadowing pneumatic actuators, for their versatility, low maintenance costs, and improved motion control. The underlying issue i think is that most linear actuators are effectively a lead screw paired with a motor in a housing