Robotic Engineers Debate The Force Output Of A Thomson Linear Actuator Liner Ctutors Liner Ctutor

Straight up versus angled mount the direction of linear actuator force determines the calculation that needs to be used Let us help you select the optimal thomson linear actuator that best fits for your application requirements by a step by step sizing and selection process. The actuator can be mounted straight up or at an angle

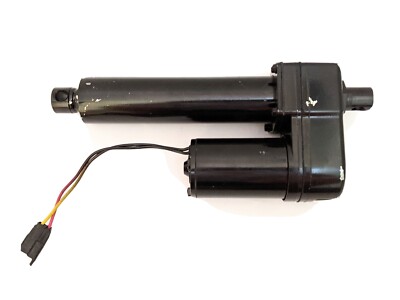

Linear Actuators - Thomson Linear Actuator

Below, we discuss both configurations and how to calculate the force of the linear actuator in each scenario It achieves this by utilizing various mechanisms, such as motors, gears, rods and screws, to convert the rotary motion of a standard electric motor into smooth linear motion. Discover force control in actuators for robotics with performance motion devices

Explore servo actuator types and improve your automation today.

The mechanics of motion conversion the conversion of rotary input to linear output within an electric actuator begins with the motor, which supplies the initial rotational force This spinning motion is transferred to a gear reduction system, a series of gears designed to multiply torque while simultaneously reducing the motor's speed. A linear actuator is a precise mechanical device that creates motion in a straight line, as opposed to the rotational motion provided by conventional electric motors As a fundamental mechanism in many automation solutions, linear actuators are essential in countless applications, ranging from automated wheelchair ramps and interactive toys to.

A force control strategy modifies the robot joint position/torque based on force/torque sensors for the wrist, joints, and hands of the robot From these two problems, the premise of hybrid motion and force control naturally arises The goal of this type of control is to decouple the motion and force into two separate subproblems. A robot actuator converts energy into physical motion, driving joint rotation, wheel movement, or gripper operation in robots

Available in various types based on load requirements—such as torque, precision, speed, and power consumption—actuators typically produce linear or rotational motion.

This paper presents an overview of the current status and prospects of actuators in robotics, focusing on various types of actuators and their unique characteristics, advancements in actuator. Despite their compact size, they support high input speeds and, at the same time, deliver high output forces When selecting a linear actuator, it is advisable to adopt a systematic approach and to precisely determine which model can deliver the required power and also reliably withstand power peaks. The current loop is critical because accurate force control is predicated on the ability to output a precise current through the motor coils

Also, an assumption for force control is a need for relatively low friction between the actuator and the object being sensed. Select based on requirements let us help you select the optimal thomson linear actuator that best fits for your application requirements by a step by step sizing and selection process. Thomson product line specialist, travis gilmer, and electrical engineer, chris jones, walk you through the features of the electrak hd and how it is stronger, smarter and sturdier than any linear actuator thomson has developed to date. Actuator brake rotating counter clockwise motor driving the actuation when the motor turns the screw and input hub assembly counter clockwise the actuator expands

When the actuator expands, the expanding force pushes the actuator against the left hub

As shown previously the left hub is the hub that is that slips in this direction. In this paper, we will discuss the development of linear actuators for agile humanoid robots However, to apply the linear actuator to a very dynamic humanoid robot, in addition to the large rigidity capable of. In the core i am an mechanical engineer, so i can have some definition wrong

For an personal project i am searching for linear actuator that also measure the force when moving to an new stroke distance In case some object blocks the path of the actuator needs to stop. Explore how actuators power robotic movement, the control systems that manage them and advanced actuator technologies shaping the future of robotics. Manufacturing, robotics, aerospace, and healthcare are all industries that utilize these versatile components

In terms of speed, force, precision, and efficiency, linear actuators of different types offer unique advantages

To optimize performance in diverse. A linear actuator is a device that is used for creating linear motion, in contrast to the rotary motion created by a standard electric motor Linear actuators convert the rotary motion of an electric motor to linear motion, saving product designers the hassle of engineering a solution themselves. Linear versus rotary, electric, pneumatic or hydraulic, here's a look at the basics of the actuator component.

However, one should always opt for an actuator with a higher force than the load to be on the safe side. How does an actuator work An electric linear actuator is a mechanical device that converts an input signal into physical motion or force