Mechanics Debate The Taper Lock Vs The Qd Bushing Standard Sizes & Types Mds

In this guide, we break down the key differences. All sizes except ja and h have a set screw over the key to help maintain the bushings position on the shaft until the cap screws are securely tightened. It allows the primary component to be flexible enough to work with a variety of shaft sizes

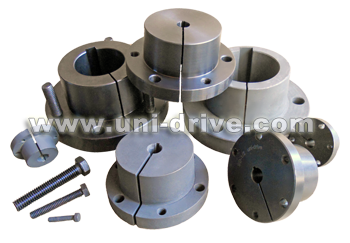

UNI-QD-BUSHING & SPLIT TAPER-BUSHING – Uni Drive System | Singapore

On the other hand, qd bushings excel in environments where flexibility, ease of installation, and frequent maintenance are the top priorities They are split through flange and taper to provide a true clamp on the shaft that is the equivalent of a shrink fit Depending on your specific needs, choosing between the two will come down to whether you value durability and stability (taper bushings) or ease of use and adaptability (qd bushings).

Whether you need a taper lock, qd, or double split taper bushing, understanding their unique features and proper installation methods will help maximize the performance and longevity of your equipment.

Qd bushing sprockets can handle higher torque and radial loads compared to taper lock sprockets The split taper bushing ensures precise alignment between the sprocket and the shaft, reducing vibrations and extending the component's lifespan. This allows for reboring under the best conditions to maintain concentricity The sawslot must be the final operation and must be performed for the bushing to properly grip the shaft

All dimensional tolerances are held prior to cutting the sawslot Qd bushings are only saw slotted thru one wall as shown in figure 1. Improper installation can damage the bushing and/or the sprocket/sheave Sprockets/sheaves are commonly mounted to a shaft with a tapered bushing that fits a mating tapered bore in the sprocket/sheave

Bushings are available in numerous bore diameters to.

Agm makes qd bushing available in inches & metric sizes and are 100% interchangeable with licensed manufacturer's oe products As the most experienced taper lock & qd bushes exporters, with taper lock bush, it is possible to achieve 'shrink fit' of pulleys, couplings etc On to shaft using simple hexagonal wrenches. The screws drive the bushing into the bore of the component where has to be installed thus compressing the inner diameter of the bushing to the keyed shaft

Position qd bushing on shaft Tighten set screw over key hand tight with standard allen wrench only Do not use excessive force Slide large end of sheave or sprocket taper bore into position over cone aligning drilled bolt holes in sheave or sprocket with tapped holes in flange of bushing

This design ensures a firm connection, providing high stability.

Same and next day delivery. A threaded shaft passes through the ball bearing unit of the bushing and is secured on the other side with a locking nut This allows sheaves and pulleys to be removed without removing the idler bushing Obviously, price, weight and convenience are minor factors in your bearing vs

Bushing decision, but if both can get the job done, who's going to pay more to do more work Compared to other bushings, like a taper lock bushing, the main advantage of a qd bushing is the ease of installation and removal. How to install a qd bushing qd bushing installation instructions involve a standard set of steps and precautions Inspect all items for dirt, grease, scratches, and any other contamination or defects.

Install m thru s bushings in the hub so that the two extra holes in the hub are located as far as possible from the bushing's saw cut.

These qd bushings provide excellent clamping force on the shaft Qd style bushings are used for sprockets, pulleys, and pulleys to increase clamping force beyond standard boring to size products that utilize only a keyway and set screws to lock onto the shaft Qd bushings are very popular and are interchangeable between manufacturers. Shop inch and metric taper lock bushings for secure shaft mounting

Browse size charts and find the right taper lock solution for your equipment. Includes complete dimensional data for bushings and hubs from size 1008 through 120100. Taper bushing series are made of high quality engineered materials with great tolerance The feature is easy to use and needs no additional alteration.

Bushing styles are not interchangeable (example

Qd must be used with qd products, tb must be used with tb products, etc.) but each type is interchangeable with the same type made by other manufacturers. Install m thru s bushings in the hub so that the two extra holes in the hub are located as far as possible from the bushing's saw cut Qd bushings quick detachable bushings are easy to install and remove

![[How do I?] - Taper Lock Bushing | The Hobby-Machinist](https://www.hobby-machinist.com/data/attachments/185/185579-6e96072908b82dcc51194147109b8c74.jpg)