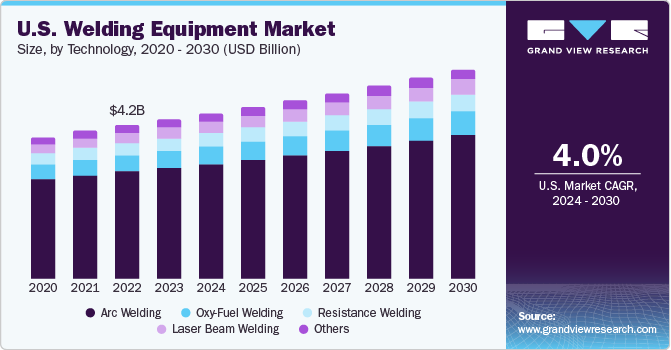

Industry Insiders Debate The Future Of Manual Welding Fab Shops Experts And To Mexico's Mining

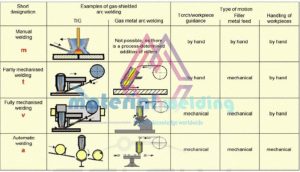

Automation and ai have already transformed metal fab, and their influence will only grow A deep dive into the trumpf truarc weld 1000 for the metal fabrication industry in the world of metal fabrication, automation continues to reshape the way companies approach manufacturing. These technologies improve speed, precision, and efficiency, while reducing the need for manual intervention.

Debate Manual | PPT

As the manufacturing industry evolves, staying ahead of emerging trends is crucial for fabrication shops looking to maintain a competitive edge The american national standard (ansi) z49.1 safety in welding, cutting, and allied processes is the industry standard for safety, and every company that welds or cuts should have a copy of this document on hand. In 2025, advancements in technology and shifting global dynamics are driving significant changes in the sector.

As an experienced welder and metal fabricator, i've had the privilege of witnessing the incredible advancements that have reshaped our industry over the years

From the shop floor to the cutting edge of technology, the world of welding and fabrication is in a constant state of evolution, driven by the relentless pursuit of efficiency, precision, and innovation Fabrication shops that adopt automation are insulating themselves from these workforce fluctuations Investing in an automated welding machine is an investment in stability It provides the consistency required to meet strict quality codes and the speed necessary to maintain margins.

The welding and fabrication industry is evolving rapidly as new technologies, workforce dynamics, and market demands reshape how shops operate Whether you're running a small fabrication shop or managing a growing welding business, staying ahead of industry trends allows you to improve efficiency, reduce costs, and compete effectively. Upgrade for the future the welding industry continues to evolve, shaped by advances in robotics, training, and process control For businesses working in fabrication, infrastructure, or energy, embracing these changes is critical

Systems like duraline's welding preheat treatment units are no longer a luxury.

As we kick off 2025, the metal fabrication industry continues to evolve, driven by advancements in technology, sustainability initiatives, and shifting market demands. Friday, may 9, 2025 show notes in this episode of state of the arc, we're diving into four major trends shaping the welding and fabrication world in 2025 How rising tariffs are impacting steel, stainless, and aluminum prices — and what shops are doing to stay competitive 🌱 topic 2 Why renewable energy projects are creating more welding demand than ever before 🧪 topic 3.

It explores factors affecting future growth, such as manufacturing costs, material efficiency, and automation trends. Our technology director guides you through the newest welding technologies and opens his thoughts regarding the future of welding. The importance of welding in automotive manufacturing with the rise of electric and lightweight vehicles, welding techniques continue to evolve, adapting to industry demands Despite automation, human welders remain indispensable, especially for precision tasks and custom fabrication.

This article originally appeared in canadian fabricating & welding

Structural steel shops face unique material handling requirements that sheet metal shops do not Oftentimes heavy fabricators have large bays with overhead cranes to move the large beams and heavy sections through workstations around the shop. Fabricators who embrace automation, invest in r&d, and adapt to market trends will thrive in this dynamic industry Bob cramer felt like he was in over his head

He had recently won a new contract that could either quadruple his fab shop's revenue—or kill it Due to unforeseen process limitations in his shop, the required investments in new equipment had grown to $2 million, and an increase in operating. Operating policies and procedures of the [companyname] quality system management acceptance Explore the top welding industry trends for 2025

Discover how automation, cobots, vr training, and data are shaping the future of welding.

Explore the process of metal fabrication, from cutting to forming, and the role it plays in creating custom products from raw materials. The future of welding automation How nexair is driving change in the industry welding shops look dramatically different today than just five years ago Cobots work alongside skilled welders

Digital workflows connect design to production seamlessly The future of welding is bright, with numerous innovations set to transform the industry From automation and advanced welding processes to digitalization, sustainability, and enhanced safety measures, these trends will improve efficiency and quality and create new opportunities for skilled professionals. We are semper fi fab shop mobile welding, llc owned and operated by james knight, a usmc veteran

We are a mobile welding service, our home office is in stanley, va.