How The Latest Dc Electric Motors Achieved 98% Power Efficiency To Calculate Motor Formula Infoupdate Org

Abb's new 56.2 mw brushless synchronous electric motor achieves over 99% efficiency, surpassing the typical 96% efficiency of industrial motors, saving 61 gwh of energy and. By doing less work, the motor consumes less energy, and the savings goes all the way back to the power plant. Within the torque generation system, the advancement of electric motors plays a pivotal role in extending range and enhancing performance

DC Electric Motors - Motordrives Australia

In recent years, we've seen considerable progress made in ev motor design and technology, covering everything from efficiency to power density. Saving a unit of energy in the belt drive operation means one less unit of energy for the motor to deliver, reducing motor output The design drivers of modern electric motors for evs are primarily focused on energy efficiency and reducing power losses

Engineers aim to improve power density and available torque while maintaining compact dimensions and low weight.

Electric motor systems (ems) cover a remarkable share of industrial power consumption In particular, little knowledge of the. With an increasing number of technologies and applications employing electric motors, rukmi dutta from the university of new south wales discusses the mechanisms and efficiency potential of electric motor systems electrical motors are the powerhouse of the industrial world, efficiently converting electrical energy into mechanical power Many critical sectors use electrical motors, including.

Understand the operation and control of electric motors and crucial for achieving optimal performance and sustainability Find different types of electric motors here. Electric motor efficiency measures how well motors convert electrical energy into mechanical power with minimal losses High efficiency improves performance, saves electricity, reduces operating costs, lowers heat, and supports sustainability in industrial power systems.

Electric motors convert electrical energy into mechanical motion for countless applications in industry, transportation, and consumer technology

Understanding their performance is crucial for energy sustainability and efficiency The degree to which a motor performs this conversion is quantified by its efficiency, which measures how much of the supplied electricity is transformed into useful. Replacing obsolete machines with new more efficient motors would lead to advantages for environment, resource exploitation, costs and competitiveness. We conducted a study using motor efficiency data to try and answer the question

What is the average efficiency of an electric motor There are no industry standards for testing and presenting motor performance figures, so it is nearly impossible to compare manufacturers during the purchasing process. By developing a greater understanding regarding electric motor efficiency and operating characteristics, you can realize some serious electric energy cost savings An often overlooked and widely misunderstood characteristic of electric motors is power factor (pf).

Electric motors are electrical machines that convert electrical energy into mechanical energy to perform useful work

In general, electric motors have three main parts A rotor, a stator, and a commutator These three parts use the attractive and repulsive forces of. Peak efficiency refers to the maximum efficiency of inverter that can be achieved at ideal output ac power, and it can be used just as a quality indicator for inverters.

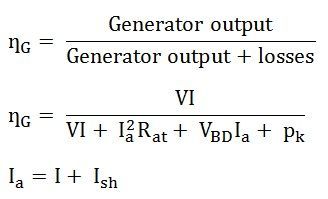

An induction motor or asynchronous motor is an ac electric motor in which the electric current in the rotor that produces torque is obtained by electromagnetic induction from the magnetic field of the stator winding [1] an induction motor therefore needs no electrical connections to the rotor. The efficiency of any machine, including an electric motor, is its useful power output divided by the total power input To be valid, however, input and output must be expressed in the same physical units.

Improving the efficiency of electric motors can save energy, reduce operating costs and improve productivity

Therefore, energy efficiency should be a key consideration when purchasing a motor Motor systems consume large amounts of electricity and can provide an opportunity for significant energy savings The annual energy cost of running a motor is usually many times greater than its initial. If i'm not mistaken electric efficiency of small brushless dc machines is 80% compared to 98% of big ac machines

Ac is used in all high power applications where efficiency is essential. An electric motor is a machine which converts electric energy into mechanical energy A system design standpoint, the drive system selection can significantly impact overall system eficiency and performance