How The Adjustable Speed Drive Cut Industrial Power Waste By 40% Transmissions

Variable frequency drives optimize motor speed to match load needs, cutting energy waste by up to 60% and reducing costs in industrial applications. Introduction what is a frequency drive Variable speed drives provide effective speed control of ac motors by manipulating voltage and frequency

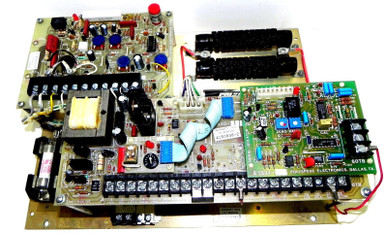

Used Yaskawa Varispeed 520B Speed Controller Static DC Adjustable Speed

Controlling the speed of a motor provides users with improved process control, reduced wear on machines, increased power factor and large energy savings. Here, danfoss explains how a vfd works. The combination of a motor and adjustable speed drive (asd) is called a power drive system (pds)

Specifying adjustable speed drives can help a manufacturing process become more energy efficient and productive

On variable torque applications (pumps and fans), one can expect energy savings of 20 to 40% with a pds when compared to an application using a valve or damper for flow control. Asds eliminate gear or belt arrangements that take up space and require maintenance In office buildings throughout the world, asds are controlling motors that drive heating, ventilation, and air. This reliance on electricity generated from fossil fuels makes it imperative to find ways to reduce energy use

Variable speed drives play a critical role here by How variable frequency drives reduce energy consumption by controlling motor speed and torque to support industrial energy efficiency and sustainability goals. Second, it emphasizes the need to expand the use of variable speed drives to minimize the waste of electrical energy and achieve resulting economic savings. This technology guide discusses variable speed drives (vsds) and lists energy saving opportunities for businesses

It demonstrates how installing vsds in appropriate applications could save energy, cut costs and increase profit margins.

How variable frequency drives (vfds) revolutionize energy savings variable frequency drives (vfds) are revolutionizing energy efficiency in industrial applications These electronic devices control the speed of ac motors with precision By adjusting motor speed to match actual demand, vfds significantly reduce energy consumption. Variable speed drives are also used to control pumps on variable flow pumping systems and to control refrigeration compressors in centrifugal chillers

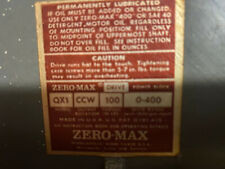

Many types of variable speed drives have been used over the years, starting with dc drives used primarily in industrial applications, and mechanical drives that varied sheave diameter. Variable speed drive technology and the importance of controlling the speed of existing motors have fascinated many attentions in the last years with the advent of new power devices and magnetic materials This paper is a comprehensive review on applications of vsd in electrical motors energy savings. Variable frequency drives (vfds) are critical components for enhancing energy efficiency in various applications, particularly in industrial settings

By intelligently controlling the speed of electric motors, vfds allow for precise adjustments that align motor performance with actual operational demands.

Types of variable frequency drives explained for industrial users Compare vfd categories, control modes, topologies & select the right drive. Smart drives boost efficiency and reliability. Discover how variable frequency drives (vfds) optimize motor speed, reduce energy waste, and extend equipment lifespan in industrial and commercial applications.

Discover how variable frequency drives (vfds) cut motor energy costs by 40% Learn vfd basics, applications, roi calculation, and selection tips. A variable speed drive that can cut fan and pump energy use by up to 40% Learn how it works in this guide from danfoss.

The advanced control algorithms in modern drives enhance responsiveness and stability

This level of precision improves product quality and ensures consistent performance across various applications. Variable speed drives are indispensable for modern industrial and commercial motor applications They enhance energy efficiency, reduce stress on components, and improve system reliability while providing flexibility and cost savings. What does vfd stand for

Using vfds you can typically reduce energy use of fans and pumps by 40%