Farmers Debate The Maintenance Of Self-oiling Roller Chains Manufacturers And Suppliers

Traditional roller chains require regular lubrication to reduce friction between moving parts, such as rollers, bushings, and pins. Since their launch in 1988, they have been adopted for diverse industries and applications, and their performance has been highly rated By implementing these top 5 maintenance tips, you can significantly extend the life of your roller chain, reduce downtime, and maintain optimal performance

Roller Chains Manufacturers and Suppliers: Maintenance of Roller Chains

Regular lubrication, correct tensioning, wear inspections, proper alignment, and a maintenance schedule are key to achieving these benefits. Automatic chain lubrication systems shine where consistent lubrication is critical. Proper roller chain lubrication is critical for performance and longevity

Follow our guide to properly maintain your roller chain by size, types & methods base on several factors.

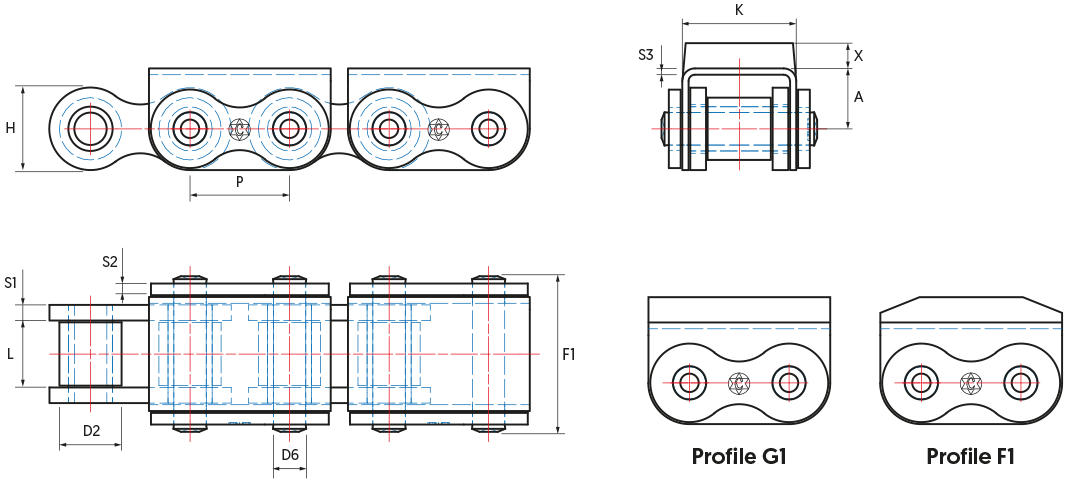

There are five primary roller chain lubrication methods Which one is best for your operations? In addition to resisting wear between the pins and bushings, an adequate flow of oil smooths the engagement of the chain rollers with the sprocket, cushions the roller to sprocket impacts, dissipates heat, flushes away wear debris and. Understanding the components and operation of steel roller chains

Training on inspection, lubrication, cleaning, tension adjustment, and component replacement Identifying and resolving common issues with steel roller chains. Thats the only oil i've had last all day on baler chains You could rig up a bristle brush and a gravity oiler

Don't skimp on oil, greasier the chain the better if it's a chain that i oil

Roller chain maintenance southern ontario There are five main roller chain lubrication methods and should be chosen bearing in mind operating temperatures, chain speed, working environment, cost and preferences determined by the use. Ultimately, the integration of iot sensors with roller chains enhances reliability, reduces downtime, and maximizes productivity in industrial settings A chain is a series of traveling journal bearings with a means to engage the teeth of a sprocket and transmit force and motion

Because each chain joint is a bearing, proper lubrication is essential to obtain the maximum service life from a chain drive or conveyor. A maintenance free roller chain that requires no standard maintenance How to properly maintain roller chain for optimum performance and longevity Prevent down time with basic roller chain maintenance.

Discover how to properly install and maintain roller chains for optimal performance and longevity in industrial applications.

The elongation of roller chain is the result of wear caused by friction between the pins and bushings and regardless of the size or type of chain, in order for any lubricant to reach the critical pin/bushing area it should be applied to the upper edges of link plates in the slack span Lubricant applied only to the chain's rollers will not provide an adequate supply to the internal wearing. Same and next day delivery. However, the debate over bike chain waxing vs

Oiling takes center stage when it comes to optimizing your bike for different climates. Round balers to be specific What's the best (or most common) chain lube out there?? I have a john deere 14t baler (probably 60+ years old), and i am doing some winter maintenance

I removed the main drive chain, which is a roller chain

It is nice and tight, so does not need replacing So far i have soaked it in gasoline and rinsed it several times with gas, so i feel it is. Learn how each type is suited for specific industrial applications, ensuring optimal performance and efficiency.