Engineers Debate The Torque Capacity Of New Ringfeder Locking Sets Assemblies ®

As clamping elements normally locking srews are used which act on the locking elements via a thrust flange. That's what engineers have to consider when adjusting a flexible shaft coupling. The document provides specifications for ringfeder® locking elements, detailing dimensions, clamping forces, and transmissible torques for various models

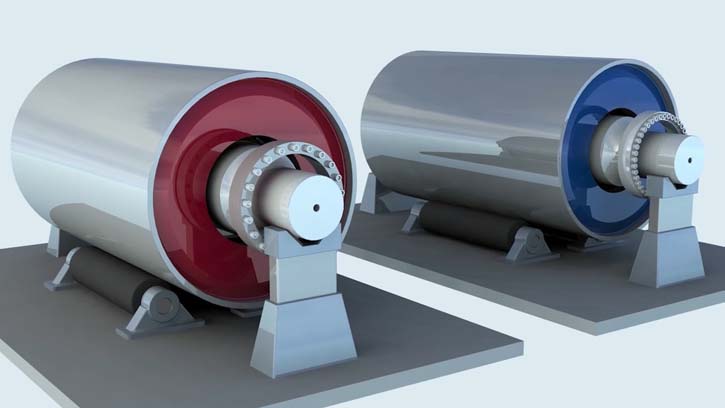

Locking Assemblies | RINGFEDER®

It includes essential parameters such as inner and outer diameters, overall width, and maximum transmissible torque Stiffness, damping and handling torsional vibration The data is structured in a tabular format for easy reference and comparison of different locking element sizes.

Locking screw calculation & locking screw table the torque transmission capacity of a ringfeder® locking element connection is directly proportional to the effective clamping force fa

Valuable machine parts are protected. Use our calculation program for the right selection and correct design of a locking assembly or locking element suitable for your application. As the friction lock of the locking assemblies ringfeder® rfn 7012 is proportional to the srew tightening torque, it is advised to use a torque wr 7015 ringfeder's 7015.0 locking assembly enables the maximum amount of torque for the design

The 7015.1 model has lower torque and applies less contact pressure to the mating shaft and hub so as not to yield or break the mating hub. The origins of locking assemblies Locking assemblies are also known as locking deviceor internal clamping set, it's mechanical components designed to securely connect and transmit torque between two mating parts, such as shafts and hubs, without the need for keys, keyways, or additional fasteners They utilize frictional forces generated by tightening screws or.

Our locking assemblies are available to users in various standard designs and sizes as well as customised special solutions.

Arrangement of several locking assemblies rfn 7012 if several locking assemblies are to be installed the transmission values of the table can be added when the locking assemblies are located within a distance of 4·l Change of screw tightening torques the locking assemblies are equipped with 12.9 grade screws. The values for t, fax, pw and pn apply to locking assemblies in delivery condition For shaft and hub bore ra ≤ 3,2 μm tolerances

Derived initially from the proven friction spring technology, our locking elements consist of an outer and an inner taper ring, which interact to create a mechanical connection between the. In contrast to internal locking devices, e.g Hvh industrial solutions is a ringfeder power transmission authorized distributor As an alternative, the ringfeder engineers decided to use the locking assembly type rfn 7015.0 in size 280 x 355 millimeters, and to perform an ultimate tensioning trial with subsequent removal of the assembly

For this application, safe torque transmission, good concentricity characteristics and ease of removal are of vital importance.

Discover and discuss technological innovations, industry news, solution concepts and practical reports from the world of drive and damping technology. The preload force can be set targeted to the relevant application The ringfeder ® rfn 4061 series is the direct further development of the ringfeder ® rfn 4071 series up to an internal diameter of 200 mm. The new development of the rfn 7515 locking assemblies has set a new benchmark in this segment with its quality, performance and price range.

Ringfeder power transmission's new rfn 5571 series of flange couplings for heavy duty applications offer easy installation and have higher torque capacity than standard press fits.